Recent News

- Building Stronger Futures: Eco-Friendly, High-Strength Mortar June 5, 2025

In a significant breakthrough for sustainable construction, a new and improved version of traditional cement mortar has been developed by Dr Geeta Devi, Assistant Professor, Department of Civil Engineering along with Dr Mohanraj Rajendran, Assistant Professor, and Mr Lokeshwaran Murugan, M.Tech Scholar have filed and published a patent titled “A Mortar Composition and a Process for its Preparation”.

In a significant breakthrough for sustainable construction, a new and improved version of traditional cement mortar has been developed by Dr Geeta Devi, Assistant Professor, Department of Civil Engineering along with Dr Mohanraj Rajendran, Assistant Professor, and Mr Lokeshwaran Murugan, M.Tech Scholar have filed and published a patent titled “A Mortar Composition and a Process for its Preparation”.This enhanced mortar becomes stronger and more durable while setting faster to reduce construction time. The improved formula absorbs less water, increasing its resistance to moisture and weather damage. It also provides better workability, making it easier to apply on construction sites. This innovation saves both time and cost in construction projects while delivering longer-lasting structural integrity, making it a valuable advancement for the building industry.

Abstract

The research presents an innovative mortar composition and a simple, scalable process for its preparation, designed to improve construction quality and efficiency. This innovative formulation incorporates polyester fibers (Recron 3s). It employs water with controlled Total Dissolved Solids (TDS) levels, resulting in remarkable improvements in compressive and flexural strength, faster setting times, and reduced water absorption. This novel formulation demonstrates up to 21.5% improvement in strength and offers a practical, eco-friendly solution for modern construction needs.A new and improved version of traditional cement mortar has been developed by adding Recron 3s polyester fibers to the mix and controlling the mixing water quality through Total Dissolved Solids (TDS) level adjustments. This enhanced mortar becomes stronger and more durable while setting faster to reduce construction time. The improved formula absorbs less water, increasing its resistance to moisture and weather damage, while also providing better workability that makes it easier to apply on construction sites. This innovation saves both time and cost in construction projects while delivering longer-lasting structural integrity, making it a valuable advancement for the building industry.

Practical Implementation & Social Impact

This new mortar composition is particularly tailored for practical use in real-world construction, including residential buildings, educational institutions like schools and colleges and infrastructure projects like bridges, pavements and stable structures for harsh environments. Some of the key performance improvements are the enhanced durability giving long-term strength, Faster setting time aiding quicker construction and better water resistance, minimising damage and deterioration.

Using this mortar composition in construction could reduce maintenance and repair costs by extending the lifespan of structures. It also supports sustainable practices by utilising recyclable polyester fibres (Recron 3s). The ability to utilise non-potable water with controlled Total Dissolved Solids (TDS) levels makes the process both eco-friendly and cost-effective in regions with limited access to clean water resources. This innovation contributes meaningfully to Sustainable Development Goals (SDGs) in infrastructure and housing, particularly in resource-limited or climate-sensitive areas.

Future Research Plans

- Scaling the mortar production for industry use.

- Exploring nano-materials and industrial by-products to further improve mortar performance and reduce environmental impact.

- Testing the composition under extreme climate conditions and integrating it with 3D printing in construction.

- Investigating automated mixing systems and AI-based optimisation of mix design for site-specific applications.

Research Team

Dr Geeta Devi – Assistant Professor, SRM University-AP

Continue reading →

Dr Mohanraj Rajendran – Assistant Professor, SRM University, Delhi NCR

Mr Lokeshwaran Murugan – M.Tech Scholar, SRM University, Delhi NCR - Gunvatta Yatra Awareness Programme on NABL Accreditation April 29, 2025

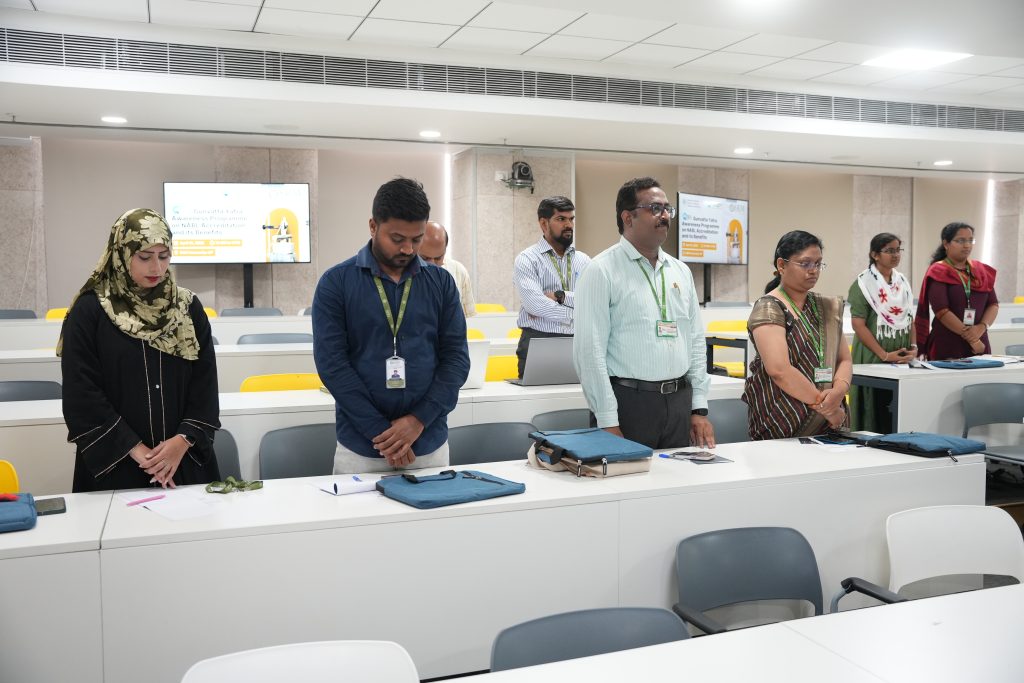

SRM University, Andhra Pradesh successfully hosted a significant one-day awareness workshop on NABL accreditation as part of the nationwide Gunvatta Yatra initiative. The event, organised by the Quality Council of India (QCI) and the National Accreditation Board for Testing and Calibration Laboratories (NABL), brought valuable knowledge about quality standards and accreditation processes directly to our campus.

SRM University, Andhra Pradesh successfully hosted a significant one-day awareness workshop on NABL accreditation as part of the nationwide Gunvatta Yatra initiative. The event, organised by the Quality Council of India (QCI) and the National Accreditation Board for Testing and Calibration Laboratories (NABL), brought valuable knowledge about quality standards and accreditation processes directly to our campus.Gunvatta Yatra is an important programme, designed to elevate quality standards across healthcare, laboratories, and MSMEs throughout India’s Tier-2, Tier-3 cities and rural areas, focused specifically on NABL accreditation processes and benefits. The workshop began with an inauguration hosted by Dr Pranav from the Department of Civil Engineering. The event started with traditional lamp lighting by dignitaries from QCI Bangalore, the Dean of Research, and the HOD of Civil Engineering, followed by an invocation song that set a positive tone for the day’s proceedings.

Dr Ranjit Thapa, Dean of Research delivered the welcome address. He emphasised that despite being a young institution, SRM AP has established itself as a research-intensive university with substantial laboratory facilities and expressed his hope to continue this momentum in the future. He articulated the huge need for the research ecosystem in Andhra Pradesh, noting the requisite for expanded laboratory infrastructure, advanced equipment, and enhanced research support throughout the region.

Mr Srikanth R, Joint Director at NABL with an impressive 30 years of professional experience in quality assurance offered comprehensive insights into the purpose and importance of laboratory accreditation. He then explained how NABL effectively helps laboratories implement international standards and detailed the recent establishment of NABL’s regional office in Bangalore to better serve southern India. Mr Srikanth emphasised accreditation’s critical role as a tool for removing technical barriers in laboratory operations and shared the significant achievement of having 9,100 laboratories accredited across India under NABL’s rigorous standards.

Following this, MrbSreeram Pinnamaraju, Assistant Director at QCI/NABL, outlined the workshop’s comprehensive agenda covering accreditation courses, application procedures, benefits of becoming accredited, and pathways to becoming an accreditor. His said that the practical, process-oriented presentations would provide participants with actionable knowledge for implementing accreditation standards within their own institutions.

As part of the broader Gunvatta Yatra movement, this workshop marked a significant step in building quality awareness and institutional capacity across India. It also reinforced SRM AP’s unwavering commitment to promoting research excellence and adherence to quality standards.

Continue reading →