- Blockchain and Analytical Hierarchy Process (AHP) in food systems June 9, 2025

Have you ever questioned whether the food on your plate is truly fresh—or where it was grown?

Have you ever questioned whether the food on your plate is truly fresh—or where it was grown?The efficiency of our food supply chain is often undermined by challenges such as limited traceability, poor communication, and rising labor costs. These disruptions can lead to food safety concerns, spoilage, and increased costs. Hence there’s a growing need for better tracking and transparency throughout the entire supply chain.

Addressing these issues, P Naga Sravanthi, Assistant Professor in the Department of Computer Science and Engineering, published a chapter titled “ Multi-Criteria Decision Making Methods and Sustainable Applications in the Digital Age” in the book Blockchain-based Supply Chain Management for Sustainable Food Production Using the Analytic Hierarchy Process (AHP) by IGI Global Publishers (US).

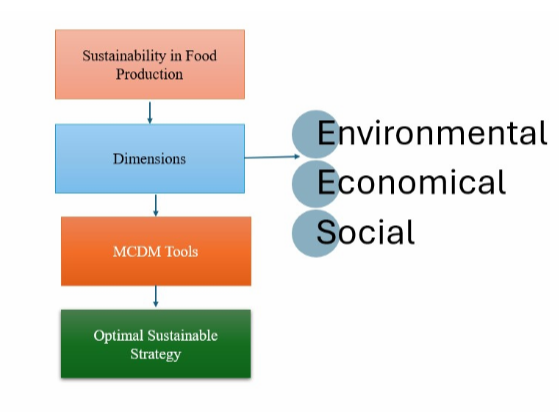

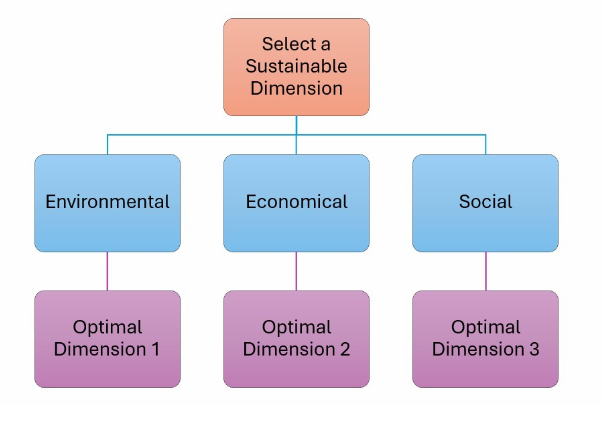

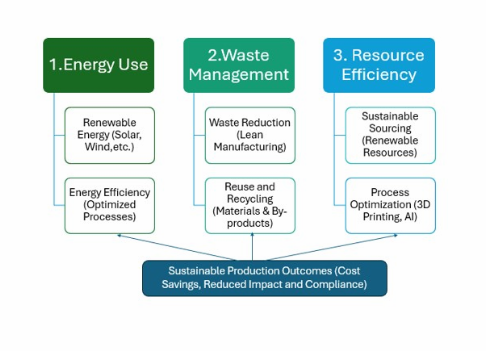

The chapter explores how blockchain can be incorporated into the food supply chain and used to track every step of the food journey. The Analytical Hierarchy Process (AHP) helps assess critical metrics like quality, cost, or environmental impact. AHP provides a transparent platform to improve food systems and make sustainable choices for all stakeholders, including farmers, sellers, and consumers.

Abstract:

This chapter discusses how blockchain technology can build transparent and trustworthy food supply chains. It combines blockchain technology with the Analytic Hierarchy Process (AHP), a structured method to rank and prioritise sustainability goals, including reducing waste, ensuring freshness, and supporting local farmers. This approach guides food producers in making smarter, eco-conscious decisions, helping them align with global sustainability goals while improving production and distribution efficiency.

Societal Impact:

This research can make a massive difference in the real-world scenario. Farmers can trace their products, suppliers can avoid fraud, and customers can get safe and fresh food. It also supports small-scale producers by giving them a voice in the supply chain. Governments and companies can use this system to ensure sustainability, reduce food loss, and build public trust in food safety and fair trade.

Future Plans :

Looking ahead, the goal is to test this blockchain-AHP model in farm-to-fork supply chains, especially in rural or emerging markets. Collaborations with agricultural cooperatives and food tech startups are in progress. Machine learning will also be integrated to improve real-time decision-making. Future research will focus on policy frameworks and community-based blockchain adoption to expand its impact on sustainable food production.

Continue reading → - Dr Bhagwat Ram June 6, 2025

- Building Stronger Futures: Eco-Friendly, High-Strength Mortar June 5, 2025

In a significant breakthrough for sustainable construction, a new and improved version of traditional cement mortar has been developed by Dr Geeta Devi, Assistant Professor, Department of Civil Engineering along with Dr Mohanraj Rajendran, Assistant Professor, and Mr Lokeshwaran Murugan, M.Tech Scholar have filed and published a patent titled “A Mortar Composition and a Process for its Preparation”.

In a significant breakthrough for sustainable construction, a new and improved version of traditional cement mortar has been developed by Dr Geeta Devi, Assistant Professor, Department of Civil Engineering along with Dr Mohanraj Rajendran, Assistant Professor, and Mr Lokeshwaran Murugan, M.Tech Scholar have filed and published a patent titled “A Mortar Composition and a Process for its Preparation”.This enhanced mortar becomes stronger and more durable while setting faster to reduce construction time. The improved formula absorbs less water, increasing its resistance to moisture and weather damage. It also provides better workability, making it easier to apply on construction sites. This innovation saves both time and cost in construction projects while delivering longer-lasting structural integrity, making it a valuable advancement for the building industry.

Abstract

The research presents an innovative mortar composition and a simple, scalable process for its preparation, designed to improve construction quality and efficiency. This innovative formulation incorporates polyester fibers (Recron 3s). It employs water with controlled Total Dissolved Solids (TDS) levels, resulting in remarkable improvements in compressive and flexural strength, faster setting times, and reduced water absorption. This novel formulation demonstrates up to 21.5% improvement in strength and offers a practical, eco-friendly solution for modern construction needs.A new and improved version of traditional cement mortar has been developed by adding Recron 3s polyester fibers to the mix and controlling the mixing water quality through Total Dissolved Solids (TDS) level adjustments. This enhanced mortar becomes stronger and more durable while setting faster to reduce construction time. The improved formula absorbs less water, increasing its resistance to moisture and weather damage, while also providing better workability that makes it easier to apply on construction sites. This innovation saves both time and cost in construction projects while delivering longer-lasting structural integrity, making it a valuable advancement for the building industry.

Practical Implementation & Social Impact

This new mortar composition is particularly tailored for practical use in real-world construction, including residential buildings, educational institutions like schools and colleges and infrastructure projects like bridges, pavements and stable structures for harsh environments. Some of the key performance improvements are the enhanced durability giving long-term strength, Faster setting time aiding quicker construction and better water resistance, minimising damage and deterioration.

Using this mortar composition in construction could reduce maintenance and repair costs by extending the lifespan of structures. It also supports sustainable practices by utilising recyclable polyester fibres (Recron 3s). The ability to utilise non-potable water with controlled Total Dissolved Solids (TDS) levels makes the process both eco-friendly and cost-effective in regions with limited access to clean water resources. This innovation contributes meaningfully to Sustainable Development Goals (SDGs) in infrastructure and housing, particularly in resource-limited or climate-sensitive areas.

Future Research Plans

- Scaling the mortar production for industry use.

- Exploring nano-materials and industrial by-products to further improve mortar performance and reduce environmental impact.

- Testing the composition under extreme climate conditions and integrating it with 3D printing in construction.

- Investigating automated mixing systems and AI-based optimisation of mix design for site-specific applications.

Research Team

Dr Geeta Devi – Assistant Professor, SRM University-AP

Continue reading →

Dr Mohanraj Rajendran – Assistant Professor, SRM University, Delhi NCR

Mr Lokeshwaran Murugan – M.Tech Scholar, SRM University, Delhi NCR - Breakthrough in Nanosecond Laser Conversion for Clean Energy June 5, 2025

The paper titled “Nanosecond Laser-Induced Conversion of Leaf-Like Co-MOF to Nanoscale Co@N-gCarbon for Enhanced Multifunctional Electrocatalytic Performance” by Dr Narayanamoorthy Bhuvanendran, Assistant Professor, Department of Environmental Science and Engineering, was published in the ChemSusChem journal with a Q1 rating with an impact factor of 7.5. The study presents a breakthrough in clean energy research with an innovative nanosecond laser-based technique that transforms metal–organic frameworks into high-performance electrocatalysts faster, more energy-efficiently, and eco-friendly.

Abstract :

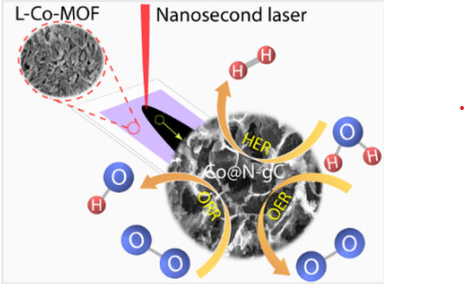

Conversion of metal–organic frameworks (MOFs) into metal-nitrogen-doped carbon (M–N–C) catalysts requires a high-temperature process and longer processing time under a protective atmosphere. This study utilises a low-energy nanosecond laser processing (LP) technique to convert aqueous synthesised 2D leaf-like Co-MOF (L-Co-MOF) into nanoscale cobalt metal encapsulated within a nitrogen-doped graphitic carbon matrix (Co@N-gC, Co-LP) in a shorter period under air atmosphere.

The laser-induced process results in the formation of Co@N-gC with smaller Co particle size, uniform distribution, and better interaction with the carbon support compared to the conventional pyrolysis process (CP). LP catalysts result in enhanced multifunctional electrocatalytic activity over CP (Co-CP) catalysts owing to the tunable metal–support interaction, higher charge transfer, and presence of multiactive sites.

Under optimised conditions (laser fluence: 5.76 mJ cm−2 and scan speed: 10 mm s−1), the Co-LP-5 catalyst exhibits better ORR performance, with onset and half-wave potentials of 0.92 and 0.76 V, respectively. Additionally, Co-LP-5 delivers excellent water-splitting performance, with OER and HER overpotentials of 380 and 280 mV, respectively, achieving an overall energy efficiency of 77.85%. Furthermore, Co-LP-5 demonstrates exceptional durability over 48 h of real-time testing, outperforming the Co-CP, and the proposed low-energy LP is viable for fabricating multifunctional catalysts.

The research focuses on developing new materials for more efficient clean energy production, specifically advanced catalysts that accelerate chemical reactions. Traditionally, creating an effective M–N–C (metal–nitrogen–carbon) catalyst requires heating metal-organic frameworks (MOFs) to high temperatures in oxygen-free environments, which is time-consuming and energy-intensive.

This study introduces a simpler, faster, and energy-saving approach using nanosecond laser pulses to transform cobalt-containing MOFs into a new material called Co@N-gC. This laser method operates in normal air, significantly reducing time and energy consumption. The resulting catalyst features smaller, evenly distributed cobalt particles that enhance interaction with the carbon support, leading to improved activity and efficiency in key energy reactions. Our laser-made catalyst, Co-LP-5, exhibited excellent performance over 48 hours, outperforming traditional methods. This breakthrough demonstrates that low-energy laser techniques can create powerful, multifunctional catalysts for clean energy more quickly, cheaply, and sustainably.

Practical implementation of the research :

We are working on developing new materials that help produce clean energy in a faster, cheaper, and more eco-friendly way. Usually, scientists use a high-heat process to convert materials called metal-organic frameworks (MOFs) into something called catalysts, which are substances that help speed up important chemical reactions, such as splitting water to produce hydrogen fuel or helping batteries and fuel cells work better.

However, the traditional method requires a lot of energy, time, and special conditions to work. In the study, we found a much simpler and faster way to make these useful catalysts. Instead of heating the material for a long time, we used a laser to quickly transform the MOF into a new material. We did this in normal air using short pulses of light from a laser, and within seconds, the material changed into a highly active form containing tiny cobalt particles surrounded by nitrogen-rich carbon. This new material works more efficiently and lasts longer than the one made by traditional heating.

Our method is not only quicker and more energy-efficient, but also easier to scale up for larger use. This laser technique can be used to create advanced materials for fuel cells, batteries, and systems that produce hydrogen from water. These technologies are crucial for clean energy and can help reduce pollution and dependence on fossil fuels.

The real-world impact of this research is significant. It can make clean energy technologies more affordable and accessible, especially in developing regions with limited energy access. It also supports the shift toward a greener economy by promoting sustainable methods and creating new opportunities in clean energy industries. In the long term, this work contributes to fighting climate change and protecting the environment by helping the world move toward cleaner, safer energy solutions.

Future Research Plans:

- Explore using different metal-based MOFs to develop a broader range of catalysts for clean energy applications.

- Optimise laser processing conditions such as energy, speed, and environment to improve the quality and performance of the final materials.

- Study the detailed mechanism of how the laser converts MOFs into active catalysts to better understand and control the process.

- Test the laser-made catalysts in actual energy devices like fuel cells and water-splitting systems to evaluate their real-world performance.

- Investigate methods to scale up the laser processing technique for larger production while keeping it cost-effective and energy efficient.

- Expand the application of these materials to other areas such as carbon dioxide reduction, hydrogen storage, or environmental sensing.

Collaborations:

Prof. Sae Youn Lee, Dongguk University, Republic of Korea.

Dr. Srinivasan Arthanari, Chungnam National University, Republic of Korea.

Continue reading →

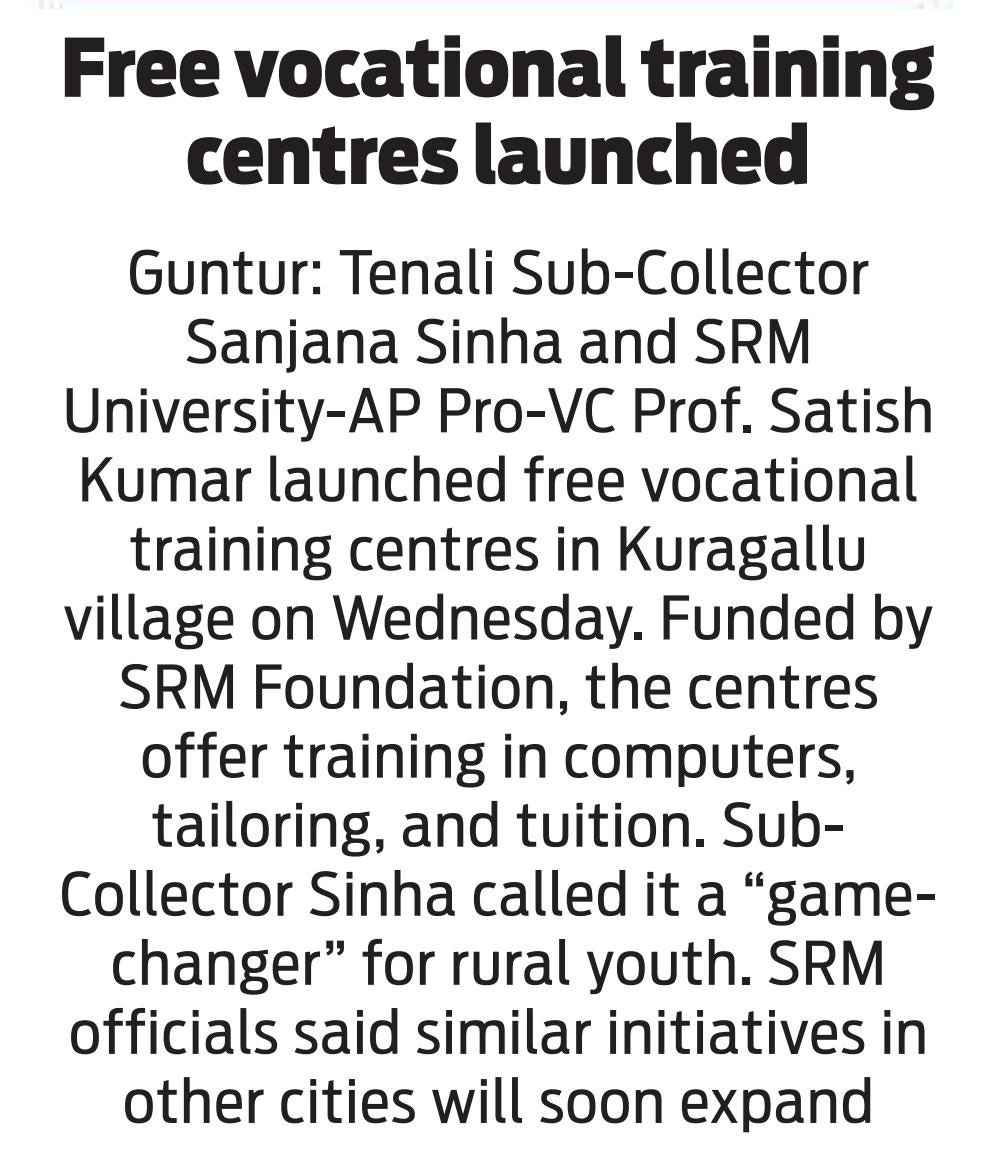

- SRM Foundation launches Vocational Training Centres for Women June 5, 2025

The Hindu

Continue reading →

The Hans India

The New Indian Express

The Pioneer

Surya

Eenadu

Palana Daily

Andhra Patrika

Andhra Prabha

Andhra Jyothi

Praja Sakthi

Sakshi

Vartha