- Industrial Meet on Fracture Mechanics: Forging Industry-Academia Partnerships June 30, 2025

The Department of Mechanical Engineering organised a focused Industrial Meet on June 21, 2025, titled “Demystifying Fracture Mechanics for Industry: Safe Design, Analysis and Operation of Pressure Vessels, Piping & Pipelines & Green Hydrogen Storage and Transportation Equipment.” This specialised workshop was designed for professionals from well-established Refinery, Petrochemical and Oil & Gas, sectors and the emerging Green Hydrogen industry.

The industry meet commenced with a brief keynote address by Dr Dipak K Chandiramani, Independent Consultant (Mumbai) & Chair, ASME PVP Division, India, on the topic “Quality Assurance in Fabrication: Perspectives from Industry Standards.” His talk laid a strong foundational understanding, setting the stage for the central theme of the meet. visited the laboratories of the Department of Mechanical Engineering and discussed opportunities for commercialising the available facilities. He expressed interest in promoting our industrial training programs on ASME’s Master Class – Advanced Learning Programs webpage and invited faculty members to participate in the upcoming ASME code development committee meetings.

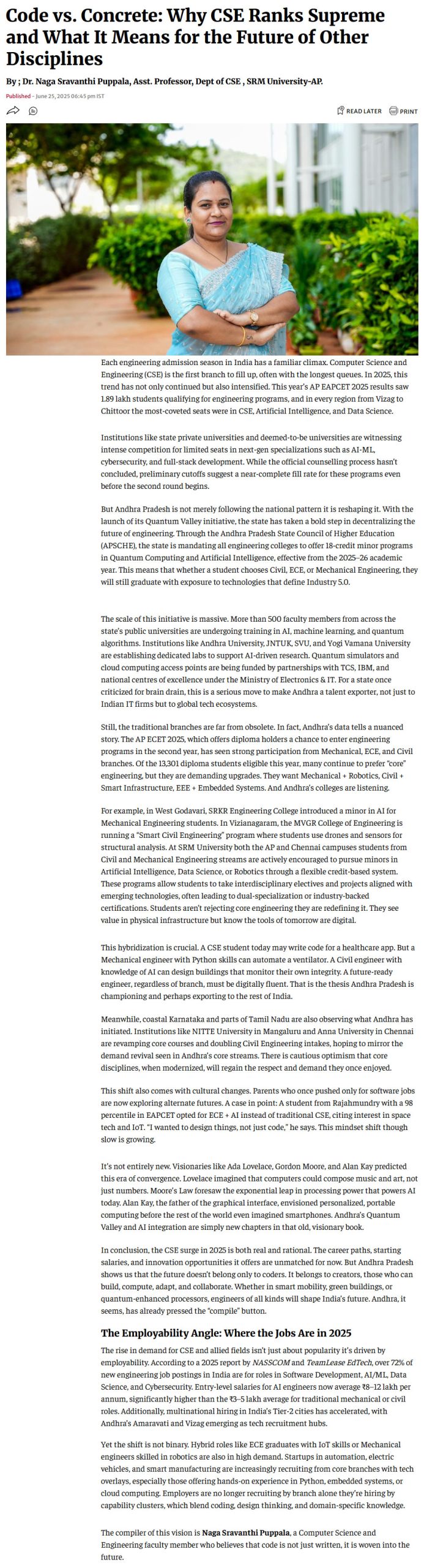

Dr Gurumurthy Kagita, Professor of Practice, Department of Mechanical Engineering, SRM AP, the main resource person for the event, shared his extensive industry experience relevant to the theme of the meet and explained the practical applications of fracture mechanics in the refinery, petrochemical, and oil & gas sectors, as well as in the emerging green hydrogen industry.

The meet began with an introduction to the key concepts of fracture mechanics, presented in a simple and accessible manner for industry professionals. Emphasis was placed on visual learning through graphics and animations rather than traditional classroom-style lectures. In the latter part of the session, the focus shifted to applying fracture mechanics in alignment with various international industry codes and standards. Several case studies were presented using in-house-developed software modules, including Brittle Fracture Screening, MPT envelopes for hydro-processing reactors, etc.

The meeting saw external participants from professionals across various industries, faculty members from the Department of Mechanical Engineering, and students, including both B.Tech. and Ph.D. scholars.

Several industry participants expressed strong interest in future collaboration with SRM University. Multiple organisations, including Anup Engineering, Jindal Renewable Pvt. Ltd., and Ratnamani Metals and Tubes Ltd., expressed interest in signing Memoranda of Understanding (MoUs) with SRM University for future collaboration in advanced engineering services. Several companies also expressed willingness to offer internships and placement opportunities to SRM AP students.

Industry representatives showed keen interest in collaborative research and consultancy projects, particularly in areas such as hydrogen pipeline design, digital twin tools, and numerical assessment of hydrogen-compatible materials.

These outcomes collectively highlight strong potential for long-term industry-academia partnerships and increased opportunities for students in training, research, and employment.

Continue reading → - Revisiting Safe and Honourable Tourism Practices post Pahalgam Attack June 27, 2025

Rising Kashmir

Continue reading →

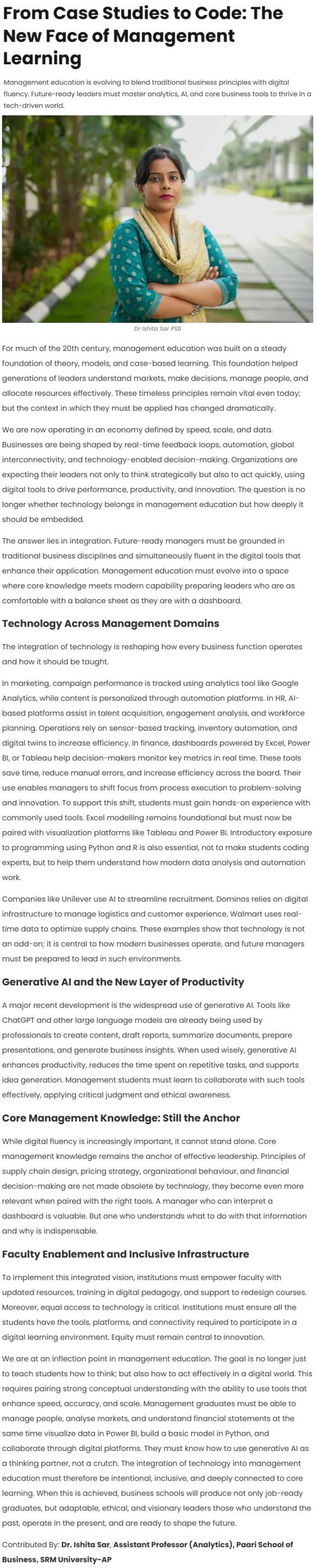

- From Case Studies to Code: The New Face of Management Learning June 27, 2025

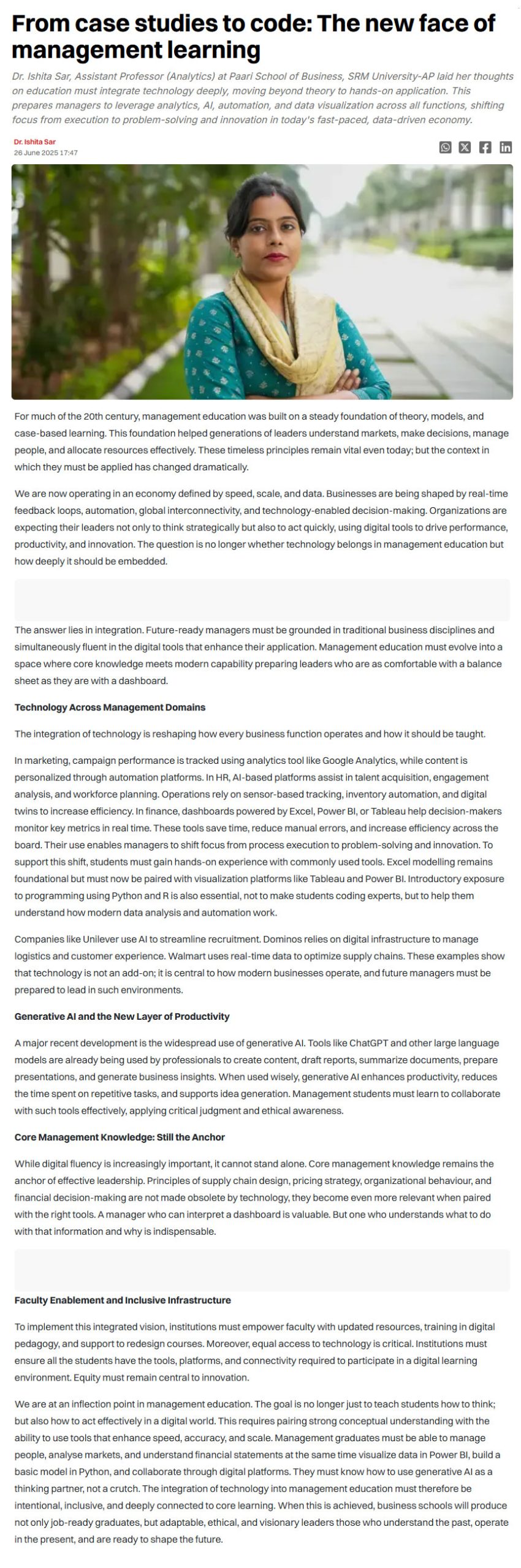

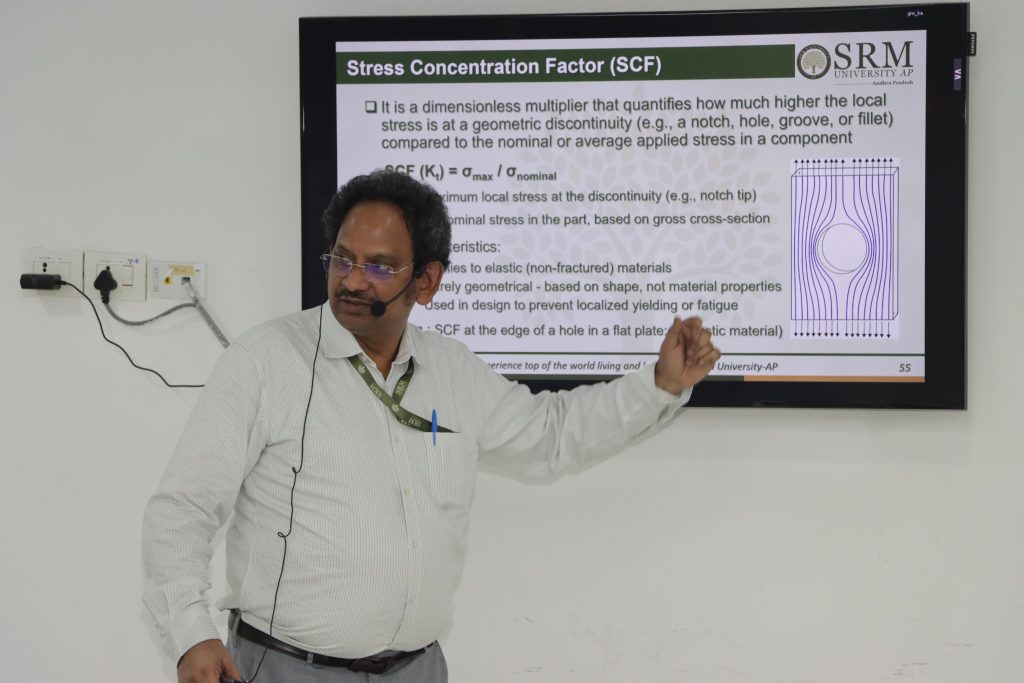

- Code vs. Concrete: Why CSE Ranks Supreme and What It Means for the Future of Other Disciplines June 27, 2025

- A Sustainable Method for Recovery of Valuable Metals from LIBs June 26, 2025

What happens when you can use natural waste like orange peels and rice husks to extract valuable metals from old batteries, electric vehicles, etc.? Exploring innovative and eco-friendly methods to recover useful metals, Dr Deblina Dutta, Assistant Professor, Department of Environmental Science and Engineering, and her research scholars, Ms Syed Suffia Iqbal and Mr Pranav Prashant Dagwar, have published a paper titled “Recovery of metals from spent lithium-ion batteries using agricultural waste, applications and circularity framework” in the prestigious Q1 journal Separation and Purification Technology having an impact factor of 8.2.

Abstract

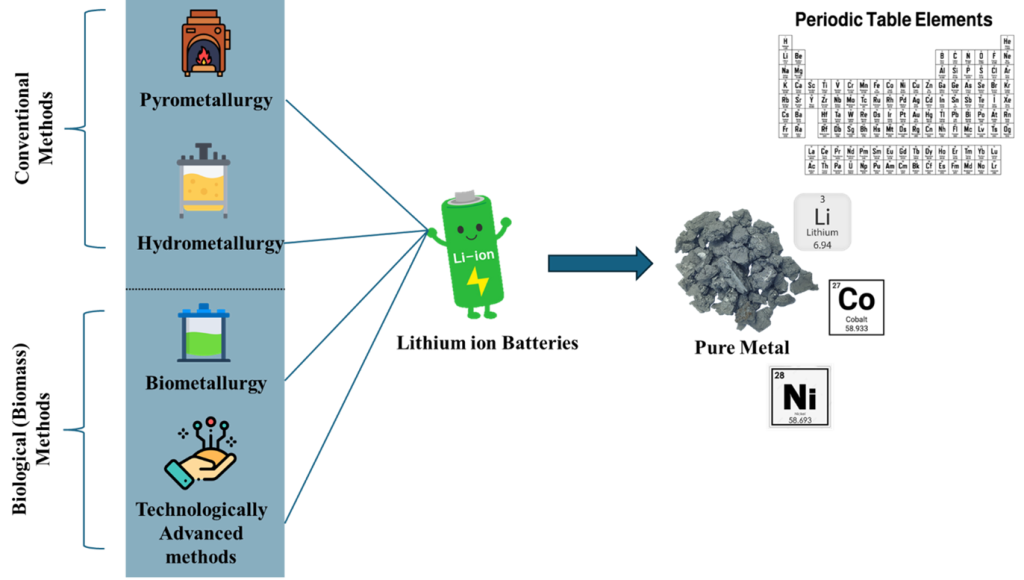

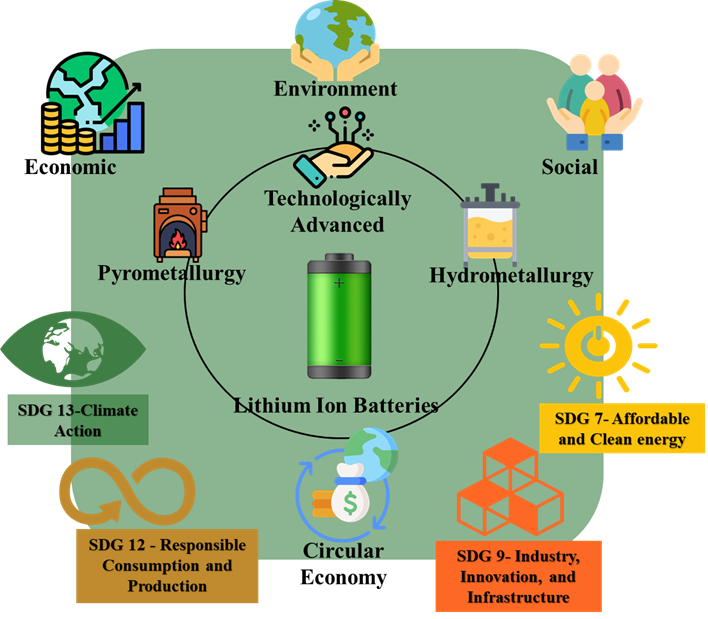

This research explores an innovative, sustainable method to recover valuable metals (Li, Co, Ni, Mn) from spent lithium-ion batteries (LIBs) using agricultural waste such as rice husk, orange peels, tea waste, and sugarcane molasses. These organic wastes serve as eco-friendly, cost-effective leaching agents. The study compares conventional and biomass-based recovery methods, evaluates environmental impacts, and aligns the approach with circular economy principles to promote green technology and resource optimization.

Practical Implementation/ Social Implications of the Research

- Eco-friendly Recycling: Offers an alternative to hazardous chemical recycling by using biodegradable, non-toxic agricultural waste.

- Waste Valorisation: Transforms agricultural waste into a valuable resource, reducing landfill and open burning.

- Resource Recovery: Helps recover critical battery metals, reducing dependence on mining.

- Circular Economy: Supports sustainability goals by promoting a closed-loop recycling system.

- Policy Relevance: Aligns with SDGs such as clean energy (SDG 7), sustainable industries (SDG 9), and responsible consumption (SDG 12).

Collaborations

- Ain Shams University, Egypt

- Central Metallurgical R&D Institute (CMRDI), Egypt

Future Research Plans

- Scale up biomass-based metal recovery to pilot or industrial level.

- Develop hybrid leaching methods combining microbes and green solvents.

- Expand to rare earth element (REE) recovery from other waste streams.

Link to the article

Fig. 2. Conventional and technologically advanced process for recycling LIBs.

Continue reading →

Fig. 9. Sustainability and circular economic applications in LIBs management.