- Top five winners of the Suggestion contest May 20, 2022

Innovative suggestions create a doorway to a world of opportunities and possibilities. The Suggestion contest conducted by the Department of Entrepreneurship and Innovation received 206 entries, and each of them was significant in one way or the other. Finding out the most impactful and meaningful suggestions among them was a hectic task, and we have five winners for the competition. Congratulations to CSE second-year student Krishna Manideep, BBA second-year student Pratibha Maurya and CSE first-year students; Vishnu Vardhan, Pranathi Jayanthi, and G Sai Rohith for making it to the top five.

Innovative suggestions create a doorway to a world of opportunities and possibilities. The Suggestion contest conducted by the Department of Entrepreneurship and Innovation received 206 entries, and each of them was significant in one way or the other. Finding out the most impactful and meaningful suggestions among them was a hectic task, and we have five winners for the competition. Congratulations to CSE second-year student Krishna Manideep, BBA second-year student Pratibha Maurya and CSE first-year students; Vishnu Vardhan, Pranathi Jayanthi, and G Sai Rohith for making it to the top five.The department has started programmes like “ExplorerHive” and “the Leader” based on the suggestions of students. Many more innovative programs are yet to come by utilising the suggestions obtained through the competition. Congratulations to the whole 206 participants for their contributions and suggestions. We value each of you and your suggestions and will try our best to put them all into practice.

Continue reading → - DST-SERB international research fellowship for Dr Raviteja May 20, 2022

SERB International Research Experience (SIRE) is a coveted opportunity for passionate researchers to collaborate with leading institutions across the globe for high-end research training in frontier areas of Science and Technology. Dr Raviteja from the Department of Civil Engineering has earned this opportunity through his resourceful project titled “Sustainable Ash based Geosynthetic Clay Liners for MSW Landfills”. The work proposes a sustainable design of solid waste landfill liners using industrial by-products like fly ash.

Municipal solid waste (MSW) landfills need to be lined at the bottom to avoid contaminant transport. The conveyance of noxious pollutants from the landfill to the natural ground can be restricted using natural or synthetic barriers. In general, natural materials like clays/bentonites in combination with geomembranes (GMB) are used in liners. However, to increase the strength properties and reduce the compressibility characteristics, bentonites are often mixed with sand. With the increased cost and scarcity of sand, there is a renewed interest among the researchers to identify an alternative material to replace sand proportion in compacted GCLs in MSW landfills. Among several materials, fly ash is proved to be a potential substitute for sand in landfill liners.

This experience will serve as an excellent opportunity to work at one of the world-renowned, state-of-the-art geoenvironmental laboratories at the University of Illinois Chicago. “I feel fortunate to collaborate with Prof. Krishna Reddy, one of the eminent researchers in the geoenvironmental research fraternity. My research at UIC would be on developing sustainable ash-based geosynthetic clay liners for MSW landfills. I also wish to pursue recent advances in this area and identify a framework for my future research”, said Dr Raviteja. The project will help him establish strong research collaborations with experts in the geotechnical labs at other US universities. He can also make field visits to identify the practical problems and direct his research toward the real-field applicability.

With an enriching research exposure at UIC, he will be able to formulate innovative and advanced research problems to enhance the visibility and applicability of his project. Presenting this work at various conferences and seminars will also attract various potential collaborations and MoU with other universities abroad. According to him, “this is a less explored domain that will immensely benefit research scholars and undergraduate students to invent new possibilities and scopes in the future”.

- Remodelling fan blades to downsize the bird strike impact May 19, 2022

Bird strikes are a crucial phenomenon that should be taken into consideration while designing aircraft. Bird strikes have been reported since the early days of flight causing fatal disasters. It is estimated that around 300 people were killed, and several aircraft were destroyed because of bird strikes. A great deal of research has been conducted to tweak the design of aircraft to bring down the impact of bird strikes. Prof Prakash Jadhav and his PhD scholar Gruhalakshmi Yella from the Department of Mechanical Engineering have published a paper offering an appropriate solution in this regard.

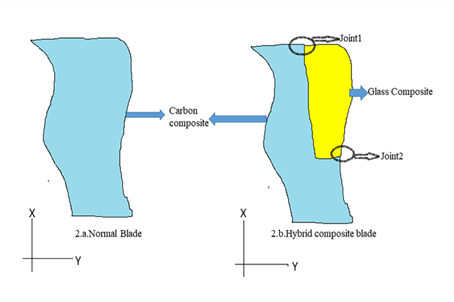

Bird strikes are a crucial phenomenon that should be taken into consideration while designing aircraft. Bird strikes have been reported since the early days of flight causing fatal disasters. It is estimated that around 300 people were killed, and several aircraft were destroyed because of bird strikes. A great deal of research has been conducted to tweak the design of aircraft to bring down the impact of bird strikes. Prof Prakash Jadhav and his PhD scholar Gruhalakshmi Yella from the Department of Mechanical Engineering have published a paper offering an appropriate solution in this regard.Their paper titled “Hybrid joint interface in composite fan blade subjected to bird strike loading” has been published in the international journal, ‘Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science’ having an impact factor of 1.76. The research puts forward an ideal solution to alter the design of the aircraft fan blades which are frequently being subjected to such collisions. The duo proposes a hybrid joint interface using two fibres instead of a single fibre.

Some delamination failures observed in the trailing edge of the blades could probably increase the effect of such bird strikes. For rectifying the delamination problem, the proposed solution is to use a material with higher strain capability such as glass fibres in the areas on the fan blade which are prone to delamination, while maintaining carbon material on the remaining blade. The concept is proved by first performing a static analysis on 3D FEA coupons with an in-built hybrid interface joint and next by performing a dynamic bird strike analysis on 3D FEA coupons and sub-element models with an in-built hybrid interface.

Abstract of the Research

Fan blades are one of the most important components of an aircraft engine. Bird strikes on fan blades have always been a cause of worry and it can cause slices of birds to hit other parts of the engine which may lead to greater damage. Bird strikes cannot be completely avoided. Although current composite blades can withstand the bird strike impact, some delamination failures are still observed on the trailing edge side of the blade, possibly due to vibration bending modes. This paper talks about using two fibres in a composite blade instead of the current single fibre one. For this to be feasible, two fibre joints at various locations on the blade must be properly designed. The design criteria used here is the lowest inter-laminar shear strain level at critical joint locations.

- Dr Sheela Singh secures patent for novel method of engine piston rings May 18, 2022

Research at SRM University-AP shows that applying a composite coating of chromium aluminum carbide (CR2 ALC) to the engine piston rings not only improves piston performance but also increases engine life, efficiency and lubrication. The university obtained a patent for the same under the title “NICKEL MOLYBDENUM ALUMINIUM (NIMOAL) – CHROMIUM ALUMINIUM CARBIDE (CR2ALC) MAX PHASE COMPOSITE COATINGS FOR AUTOMOTIVE APPLICATIONS AND A METHOD FOR MAKING THE SAME”.

For any vehicle to run efficiently for a long time, its engine must be good. The rings on piston further improve the engine performance. It is in this context that many efforts are being made by scientists to develop piston rings with the new scientific technologies. Dr Sheela Singh, Associate Professor in the Department of Mechanical Engineering at SRM AP, has been conducting comprehensive research on the subject for three years with research student Deepak Davis.

The piston rings of motor vehicles currently on the market have a coating with nickel molybdenum aluminum. SRM University-AP researchers say it would be better to use a composite coating made with chromium aluminum carbide instead. If the piston rings have high velocity and lubrication properties, their rigidity is good and it is better to use chromium aluminum carbide (CR2LC).

The Patent Certificate is issued by the Patent Office, Government of India, after thorough examination. University President Dr Satyanarayanan, Vice-Chancellor Prof V S Rao, Pro Vice-Chancellor Prof D Narayana Rao and others lauded Dr Sheela Singh and Deepak Davis for their fervent research and innovation. This is the second patent granted to SRM University-AP.

Continue reading → - PAN/PVP blend nanofiber air filtration mechanism May 18, 2022

Studies and research on air pollution have sparked worldwide interest in the recent decades to overcome the imminent threat of air pollution. The air filtration mechanism is one of the efficient ways to capture particulate matter (PM) and purify the air. An innovatory air filtration mechanism blending polyacrylonitrile (PAN)/polyvinylpyrrolidone (PVP) polymer nanofibers has been proposed by Prof Ranjit Thapa and his PhD scholar Deepak S Gavali from the Department of Physics.

The paper “Low Basis Weight Polyacrylonitrile/Polyvinylpyrrolidone Blended Nanofiber Membranes for Efficient Particulate Matter Capture” was published in collaboration with Applied NanoPhysics Laboratory, Department of Physics and Nanotechnology, SRM Institute of Science and Technology, Kattankulathur. It was featured in the journal ‘ACS Applied Polymer Materials’ having an Impact Factor of 4.09.

In the twenty-first century, air pollution is a major problem facing human and environmental health. Every year, millions of people die, mostly in developing nations, owing to the aggravating level of air pollution. According to the World Health Organization (WHO), 92 per cent of the people live in places where the air quality level has crossed the WHO limits. Particulate matter (PM) (solid or liquid particles with different aerodynamic diameters), nitrogen dioxide (NO2), ozone (O3), and others are the relevant air contaminants.

In low-income cities, the effect of PM 2.5 pollution is high due to high urban air pollution. Even at very low concentrations, PM 2.5 (particles with an aerodynamic diameter less than 2.5 µm) pollution has health consequences. Air filtration is one of the best remedies to tackle such problems and maintain a clean environment for humans. Among the available air filter materials, fiber-based air filters have proven to be the most potentially effective treatment, due to their high porosity, high surface area, lightweight, etc.

This study relies on a careful design that blends PAN and PVP fibers. The resultant nanofiber material is utilized to overcome the low air pressure resistance issue with high filtration efficiency. Large-scale free-standing nanofibers were obtained by a simple peeling-off process. The morphology, chemical interaction between the filter media and PM pollutant; and filtration properties were investigated. Compared to commercial mask, the semi- high-efficiency particulate air (HEPA) filter media, PAN/PVP filter medium showed superior performance in PM 2.5 filtration. Furthermore, the intermolecular interactions between PMs and nanofibers were analyzed by DFT calculations. With constant optimization of synthesis conditions, the synthesized air filters achieved high filtration efficiency for PM removal and showed great potential for practical application.

Abstract of the Research

Particulate matter (PM) in air frequently poses a serious threat to human health. Smaller PM can easily enter into the alveolus and blood vessels with airflow. This work reports the first polyacrylonitrile (PAN)/polyvinylpyrrolidone (PVP) polymer blend nanofiber filter media for effectively capturing PM. Density functional theory (DFT) calculations are used to investigate the effect of the blending of two polymers on the dipole moment and the electrostatic potential. Based on the DFT calculations of the intermolecular interactions between nanofibers and PM, the PAN/PVP heteromolecular percentage is considered for experimental synthesis, which can provide better performance in the filtration of pollutants. The composite PAN/PVP fiber network was successfully developed and optimized to cope with complex environments during the actual filtration process. The role of the blending ratio of PAN and PVP in wt % was explored on PM 2.5 capture, and the refined ratio overcame the conflict between high filtration efficiency and low air pressure resistance. The air filter medium PAN/PVP (6:2) possesses an extremely high air filtration efficiency of 92% under a very low pressure drop of 18 Pa for a 0.5 g m–2 basis weight. Both polar and nonpolar functional groups in blend nanofibers promoted significantly the electrostatic attraction and improved the filtration efficiency under static and dynamic airflow. The PAN/PVP nanofiber membranes maintain outstanding air filtration under different temperature and humidity conditions. This study will shed light on the fabrication of high-efficiency low-basis weight nanofiber filter media as an end product.

Continue reading →