Pioneering the Future: Ultrafine MgAl2O4 Particle-Stabilised Mg-3Ca Alloy Foams

The Department of Mechanical Engineering is thrilled to announce a significant breakthrough in materials science has been achieved through the diligent research efforts of Prof. G S Vinod Kumar, Professor and Head of the Department and his Ph.D. scholar, Mr Dipak Bhosale in their latest paper, “Production, stability and properties of ultrafine MgAl2O4 (Spinel) particles stabilized Mg-3Ca alloy foams”. The study focuses on the development and detailed analysis of Mg–3Ca alloy foams, uniquely enhanced by ultrafine MgAl2O4 (spinel) particles. This innovative research outlines a novel methodology for improving the mechanical properties of magnesium foams, providing unparalleled advantages for a multitude of industrial applications.

Abstract

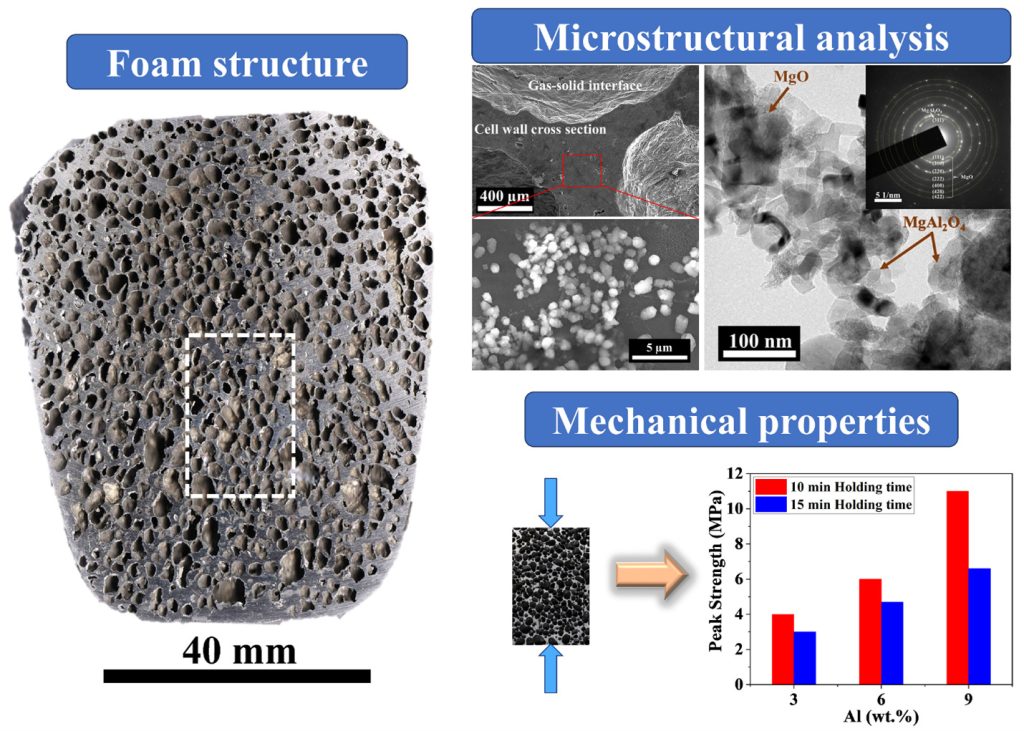

The present work reports the synthesis and mechanical behaviour studies of Mg–3Ca alloy foams stabilized by ultrafine MgAl 2 O 4 (spinel) particles. The MgAl 2 O 4 particles were created in-situ in the Mg–3Ca alloy melt through the reaction of Mg, Al and O. Foaming was done by adding dolomite (CaMg(CO 3 ) 2 ) as a blowing agent in the melt. The foaming behaviour was studied for different MgAl 2 O 4 content in Mg–3Ca and holding times (10 and 15 min). The study reveals that the presence of MgAl 2 O 4 significantly influences the foaming behaviour of Mg–3Ca alloy resulting in equiaxed cell structure, uniform cell size distribution, and higher expansion in comparison to the Mg–3Ca alloy foam, which contains only MgO and CaO. An in-depth phase and microstructural analysis were performed to investigate the particles present in the gas-solid interface of the foam that contribute to foam stabilization. The quasi-static compression studies of foams exhibited better compressive strength (≈3–11 MPa) and energy absorption capacity (≈1.3–5.7 MJ/m3) in comparison to the Mg foams reported in the literature. The ductility of the Mg foams was also measured and compared with that of existing aluminium foams.

Research Highlights:-

- Innovative Synthesis: The MgAl2O4 particles are synthesized in situ within the Mg–3Ca alloy melt via a controlled reaction involving Mg, Al, and O. This process ensures the uniform dispersion of spinel particles, which is critical for the foam’s structural integrity and performance.

- Foaming Process: By employing dolomite (CaMg(CO3)2) as a blowing agent, the research team meticulously explored the foaming behaviour under various MgAl2O4 contents and holding times (10 and 15 min). The findings highlight a marked improvement in foam expansion and stability.

- Structural and Mechanical Analysis: Through comprehensive phase and microstructural analyses, the pivotal role of MgAl2O4 particles at the gas-solid interface in stabilizing the foam structure was uncovered. Quasi-static compression tests revealed outstanding compressive strength (≈3–11 MPa) and energy absorption capacity (≈1.3–5.7 MJ/m3), surpassing existing benchmarks for magnesium foams.

Key Properties and Applications:-

- Low Density & High Strength-to-Weight Ratio: The Mg–3Ca alloy foams showcase an optimal balance of low density and high mechanical strength, rendering them ideal for lightweight structural applications.

- Enhanced Energy Absorption: Their unique cellular structure provides superior energy absorption capabilities, suitable for impact and crash-resistant applications.

- Biocompatibility: Owing to magnesium’s biocompatibility, these foams are highly promising for biomedical applications, including bone implants and scaffolds for tissue engineering.

- Thermal Conductivity & Corrosion Resistance: Additionally, these foams exhibit advantageous thermal and corrosion-resistant properties, broadening their applicability across various environmental conditions.

Transformative Impact Across Industries:-

- Aerospace and Automotive: The significant weight reduction capabilities, coupled with uncompromised strength, position the Mg–3Ca alloy foams as revolutionary materials for component design in the aerospace and automotive sectors.

- Biomedical: Their biocompatible nature and structural characteristics make these foams an excellent option for medical implants and scaffolds, poised to improve patient outcomes in orthopaedics and tissue engineering significantly.

- Energy and Beyond: From thermal management solutions in renewable energy systems to applications in sports equipment, the potential uses for these magnesium foams are extensive and diverse, heralding a new chapter in material science.

This groundbreaking research not only advances the field of magnesium foam technology but also paves the way for new possibilities in lightweight, high-performance materials across various industries. The team is dedicated to further exploring the capabilities of these innovative materials and eagerly anticipates partnering with industry stakeholders to transition these advancements from the laboratory to commercial applications.

- Published in Departmental News, Mechanical Engineering NEWS, News, Research News

Innovating the Future: Patent Granted to Prof. Vinod Kumar and Dipak Bhosale

In the era of scientific advancement, Prof. G S Vinod Kumar, HoD and his Research Scholar, Dipak Nandkumar Bhosale, from the Department of Mechanical Engineering at SRM University-AP, shine as a beacon of inspiration. The teacher-student duo were granted a patent for their research titled “Closed Cell Magnesium Alloy Foams Stabilized by Fly Ash Particles and A Method for Preparation for the Same.” This patent stands as a testament to their relentless pursuit and unwavering commitment to science.

Kudos to Prof. G S Vinod Kumar and Mr Dipak Nandkumar Bhosale for their exemplary dedication and foresight. Here’s an abstract of their patent-winning research.

Abstract:

A magnesium metal foam product enhanced with fly ash particles demonstrates versatility across multiple applications, including space, automotive, civil engineering, and marine uses. The stability of this magnesium alloy foam is attributed to the incorporation of fly ash particles, particularly alumina silicate (Al2SiO5) cenospheres. These cenospheres, hollow spheres derived from fly ash, serve as effective stabilisers for the magnesium alloy foam. The preparation involves reinforcing magnesium foamable precursors with fly ash particles, facilitating optimal foaming. The presence of fly ash particles ensures the stability of the liquid foam until solidification, resulting in a foam with a superior pore structure. With a contact angle ranging between 70° to 90°, the particles exhibit prolonged interaction with the liquid metal without agglomeration, dissolution, or reaction. This characteristic contributes to the attainment of desirable qualities essential for diverse applications.

Practical Application:

1. Aerospace: Magnesium foams can be used in lightweight structural components, thermal insulation, and vibration-damping systems in aerospace applications.

2. Automotive: In the automotive industry, magnesium foams find applications in lightweight body panels, crash absorbers, and acoustic insulation.

3. Biomedical: Due to their biocompatibility, magnesium foams are utilised in medical implants, such as bone fixation plates, and as scaffolds for tissue engineering.

4. Energy: These foams can be employed in thermal management systems, heat exchangers, and as structural components in renewable energy systems.

5. Sports and Leisure: Magnesium foams can be used in sports equipment such as helmets, pads, and protective gear due to their lightweight and impact-absorbing properties.

Patent Grant Number: 50830

- Published in Departmental News, Mechanical Engineering NEWS, News, Research News

SRM AP and TITAN COMPANY LIMITED Jointly Filed an Industrial Patent

SRM University-AP and TITAN COMPANY LIMITED, a leading jewellery brand in India, have collaborated to engineer novel jewellery products using advanced materials and technologies. The joint research project, led by HOD Prof. G S Vinod Kumar and Ph.D. Scholar Dipak Nandkumar Bhosale, Department of Mechanical Engineering, has resulted in a new method of manufacturing foamed gold alloy that is lighter, stronger, and more durable than conventional gold jewellery.

SRM University-AP and TITAN COMPANY LIMITED, a leading jewellery brand in India, have collaborated to engineer novel jewellery products using advanced materials and technologies. The joint research project, led by HOD Prof. G S Vinod Kumar and Ph.D. Scholar Dipak Nandkumar Bhosale, Department of Mechanical Engineering, has resulted in a new method of manufacturing foamed gold alloy that is lighter, stronger, and more durable than conventional gold jewellery.

A joint patent between SRM University-AP and TITAN COMPANY LIMITED has been filed for this innovative method of manufacturing foamed gold alloys. The jewellery products made from this material are currently available in TITAN showrooms under the brand name TANISHQ. The customers can enjoy the benefits of wearing lightweight and high-strength jewellery, which also has a high aesthetic appeal and value.

The collaboration between SRM University-AP and TITAN COMPANY LIMITED exemplifies how academia and industry can work together to create novel and useful products for society. The joint research project also provides an opportunity for the students and faculty of SRM University-AP to gain exposure and experience in the field of jewellery engineering and design and to contribute to advancing science and technology.

Abstract

The current innovation introduces a method for producing foamed gold alloy utilising a liquid metallurgical approach. Gas-releasing agents such as hydrides and carbonates are employed in the manufacturing process. Both 18K and 22K alloys are subjected to foaming in this invention. The resulting foams are stabilised by oxides generated in-situ as well as oxides added externally. These foamed gold alloys exhibit ultra-lower density. The foaming process is successfully executed using both interrupted and uninterrupted methods. These foamed gold alloys find applications in various fields including Jewellery and medical implants.

The title of patent in the citation format

“G. S. Vinod Kumar, Dipak Nandkumar Bhosale. A METHOD OF MANUFACTURING A FOAMED GOLD ALLOY. Indian Patent application number 202341059195 filed Sep 04, 2023”

Patent Application number

202341059195

Inventors

1. G. S. Vinod Kumar 2. Dipak Nandkumar Bhosale

- Published in Departmental News, Mechanical Engineering NEWS, News, Research News

DST-FIST Grant of Rs 1.4 Crores for Mechanical Engineering Department

SRM University-AP shares a momentous achievement as the Mechanical Engineering department has been awarded a financial grant of Rs 1.4 crores under the prestigious FIST (Fund for Improvement of S&T Infrastructure) by DST (Department of Science and Technology) Government of India.

The equipment proposed under the FIST grant is High-Resolution X-ray Micro Computed Tomographic Scanner that will help Materials Scientists, Engineers, Manufacturers and Researchers investigate internal structures, pore flaws of metallic, polymer and ceramic samples/ components non-destructively. This state-of-the-art facility will promote R&D activities in new and emerging areas of Materials Science Engineering and Manufacturing. Additionally, it seeks to attract fresh talents to the university, fostering an environment of innovation and scientific excellence. The established facility will be available to internal and external users (from academic institutions, research labs, manufacturing Industries, MSMEs and Startups.

The grant, awarded for a duration of 5 years, is a testament to the unwavering commitment of SRM University-AP to providing cutting-edge resources for the advancement of scientific studies. This achievement results from the exceptional efforts put forth by the faculty members of the Department of Mechanical Engineering of the university. Their dedication, expertise, and commitment to academics and research played a pivotal role in securing this grant amidst tough competition.

Prof. Manoj K Arora, Vice Chancellor, SRM University-AP proudly remarked, “This grant will not only enhance our research capabilities but also provide a platform for our students and faculty members to explore new avenues in the field.” Prof. G S Vinod Kumar, Head of the Mechanical Department, expressed his delight that the grant will be utilised for advanced characterisation and diagnostic research in the area of Materials and Manufacturing. It will also be used to strengthen the postgraduate and doctoral research facilities in the mechanical engineering department.

The Institute applauds the Mechanical Engineering department for proving their mettle and emerging success among departments from various universities/institutes, both government-funded and private, in the national level competition for the DST-FIST grant. SRM University-AP is confident that this financial support will propel the Mechanical Engineering department to new heights of success and enable them to contribute significantly to the scientific community. The institution remains committed to fostering an environment that encourages research, innovation, and knowledge creation.

- Published in Departmental News, Mechanical Engineering NEWS, News, Research News

Best Paper Award: Accorded to Dr Supen Kumar at MRAE 2023

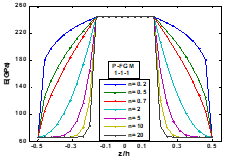

The Department of Mechanical Engineering is delighted to share that Dr Supen Kumar Sah, Assistant Professor, Department of Mechanical Engineering, has received the best paper award for his paper titled “Free Vibration Analysis of Functionally Graded Material Sandwich Plate Using Refined Shear Deformation Theory” in the 2nd International Conference on Modern Research in Aerospace Engineering (MRAE 2023). Dr Supen collaborated with Saloni Malviya of VIT, Bhopal, for the research paper. The paper explores the intricate dynamics of functionally graded material sandwich plates, employing a refined deformation theory. Dr Sah’s exceptional work has not only contributed to the scientific community but has also demonstrated his dedication and passion for advancing knowledge in the field of materials science and engineering.

Abstract

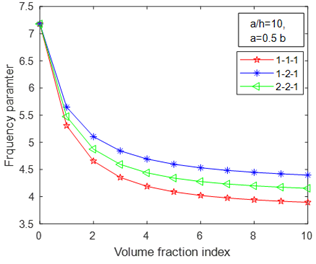

In the present study, free vibration analysis of a functionally graded material sandwich plate has been carried out using refined shear deformation theory. The shear correction factor is not needed since the parabolic variation of shear strain through the thickness is in such a way that shear stresses vanish on the plate surfaces. Hamilton’s principle is used for the derivation of the equation of motion for the theory. Additionally, Navier’s solution is used to obtain the eigenvalue equation for the sandwich plate. The three variants of sandwich plate are chosen for the analysis. To carry out the free vibration analysis three different types of FGM sandwich plate models namely 1-1-1, 1-2-1, and 2-2-1 have been considered. A power law defines the volume fraction index and the material properties of the individual layers of the sandwich plate. Lastly, the impact of parameters such as volume fraction, aspect ratio, and length-to-width ratio on frequency parameters is investigated.

Future Research Plans

• Modelling and Analysis of porous uni and multi-directional Functionally Graded Material (FGM) plates to obtain the impact of porosity distributions over structural responses.

• Analytical and finite Element Solutions for static and dynamic response of FGM sandwich plates employing non-polynomial shear deformation theories under elastic foundation.

- Published in Departmental News, Faculty Achievements, Mechanical Engineering NEWS, News, Research News

IIT Bombay Professor Delivers Distinguished Lecture at SRM University-AP

“If we start working today towards developing LTA systems, in 10 years India will lead the sustainable air transportation” esteemed academician, Prof. Rajkumar S Pant, Professor of Aerospace Engineering stated in his lecture at SRM University-AP. The seasoned expert from the prestigious institute of IIT Bombay delivered a lecture on “The Design and Development of Lighter Than Air Systems” at SRM university-AP on October 16, 2023, as part of the Distinguished Lecture Series 2023 organised by the Department of Mechanical Engineering. The lecture extensively discussed the latest developments in the area of conceptual design, sizing, design, development and flight/field testing of LTA Systems.

In his lecture, Prof. Pant encouraged students to explore the dynamics of Lighter Than Air Systems, beginning with aerostats and then gradually proceeding to more complex airships. The session highlighted the disaster of Hindenburg, breaking the myth that airship transportation is dangerous and unreliable. Prof. Pant engaged the session with video presentations on the building, developing and working of airships and aerostats that have been conducted at the Lighter-Than-Air Systems Laboratory of IIT Bombay. His lecture also showcased some of the research and development activities that have been carried out in the LTA Systems Laboratory of IIT Bombay including Project HERCARA, and other projects carried out in collaboration with ISRO and DRDO.

The distinguished lecture was followed by a workshop on “Sizing of Reusable Indoor Hot Air Balloon (RIHAB)”. The workshop provided the students with practical knowledge and hands-on experience on LTE systems and vehicles inducing research interest in the domain of aerospace engineering and sustainable air transportation. Prof. Ranjit Thapa, Dean – Research, Prof. Prakash Jadhav, Head – Department of Mechanical Engineering, faculty and students at the university actively participated in the lecture and the workshop.

- Published in Departmental News, Mechanical Engineering NEWS, News

AutoNxt Automation visits campus

Interactive session with industrial inventors

World’s First Electric, Autonomous Tractor

World’s First Electric, Autonomous TractorKaustubh Dhonde, CEO, Swadeep Pillarisetti, Advisor and Board Director, Sachin Gowda, Embedded Engineer, and Aswanth Mulupuri, Intern, Department of Automation of AutoNxt Automation – an innovative Mumbai based startup, visited SRM University AP, Andhra Pradesh for a two-day program as a part of the National Science Day celebration at the campus. The company demonstrated their latest technological marvel, the World’s First Electric, Autonomous Tractor. “A lot of research is conducted globally with multiple companies working on the automation of on-road vehicles. However, off-road vehicles’ automation has hardly been touched upon previously, although there are less variables being controlled environments like farms, industrial plants, etc where it is more feasible a solution”, says Mr. Swadeep who has been advising the company which has brought about a revolutionary breakthrough in the domain of Indian agriculture.

Some of the exceptional features of the Electric Automated Tractor include fully electric drivetrain, low NVH (Noise, Vibration and Harshness) levels, mobile application for interaction with the tractor, live tracking, geo fencing capabilities, battery and system status reports on mobile app, obstacle detection technology and optional automatic hydraulic control of implements. The company is also planning to develop a common charging point that will use free energy sources.

Students marveling at the automated tractor

Students marveling at the automated tractor

Demonstration by the CEO

AutoNxt Automation has created its niche by offering cost-effective and energy-efficient solutions to farming problems. Mr. Kaustubh believes “It is important that technology reaches out to the entire farmer class”. He further explains the crises of the Indian agricultural system that can be resolved using the Electric Automated Tractors, “The harvesting timeframe is narrow which increases the demand of skilled labour during this season, exponentially enhancing the cumulative cost of farming. The fully automated tractors embedded with camera identification systems and sensors reduce the operational expenses up to 4 times. Also, the IoT sensors give real-time feedbacks ensuring accuracy in tilling, ploughing, and spraying insecticide.”

The representatives of the company held a demonstrative session with the students and faculty on 26th February 2020, where they introduced the tractor and explained its technological viabilities. An interactive session was also held with the students on the same day. The session enabled the students to identify the practical applications of their acquired theoretical knowledge. The entrepreneurs inspired the students to create an impactful change that will eventually benefit society as a whole. Also, it creates an opportunity for them to be closely associated with people from the industry as well as the research domain. On the following day, a presentation was made to the faculty members of SRM AP to trigger discussions on technologies used by the Electric Automated Tractor. In the end, Mr. Kaustubh and Mr. Swadeep expressed their intent to involve students to work on real-time projects with the company, along with taking assistance from the faculty members to overcome hurdles pertaining to AI/ML technologies. Mr. Swadeep says, “The students will be exposed to real case studies, contribute to the improvement of the country, and in the process earn many accolades”.

Sachin Gowda interacting with the students

- Published in Mechanical Engineering NEWS, News

Cost-effective shield against Coronavirus

Dr. Panchagunula Jayaprakash designs an improved alternative to regular masks

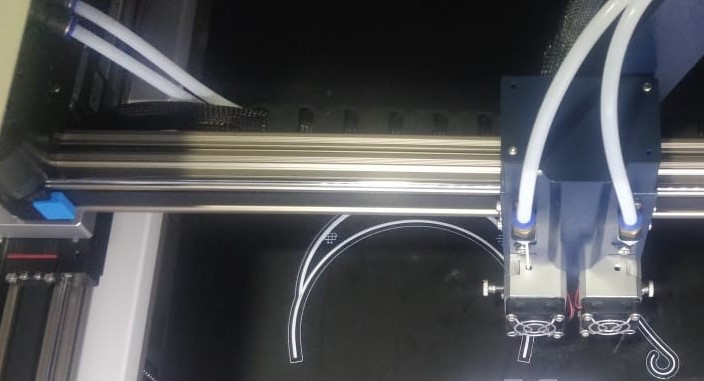

Dr. Panchagunula Jayaprakash, Assistant Professor, Department of Mechanical Engineering, has designed a FACE SHIELD embedded with 3D printing technology. During this pandemic that has led to an unprecedented global crisis, this face protection devised to protect users from the Novel Coronavirus, is made available at the minimum rate of Rs. 20 each. The major drawback of the commercially available Face Shields for engineering applications is its heavy weight which causes discomfort if worn for a longer period of time. This face mask that uses 3D printing technology alleviates the limitations of the regular masks currently used by doctors, policemen, and journalists.

Head mounted Face Sheild

Head mounted Face Sheild

“With the advent of Covid-19, and due to the shortage of personal protective equipment, the health workers such as Doctors, Sanitary staff and Police are also getting infected. As they are the backbone of the society, I thought of designing a light weight Face Shield using 3D Printing (3DP) or Additive Manufacturing technique. The rudimentary advantages of 3D printing technology is the design flexibility and less lead time to manufacturing. “, explains Dr. Jayaprakash.

Creation of CAD model

Creation of CAD model

3D Printing

3D Printing

The regular masks barely cover the nose and mouth, whereas the Face Shield will be able to protect the eyes, mouth, nose, and ears so that one cannot get infected by the virus. Some of the medical and police personnel who use the regular masks suffer from facial irritation, making the Face Shield a comfortable and more effective alternative for all government officials on Covid-19 duty.

Physical component

Physical component

Dr. Jayapraksh further says, “While manufacturing the Face Shield, 3D printing technology is used for designing a headband, upon which a 100 micron thick transparent plastic sheet is attached to ensure superior protection against the virus. It prevents air, dust, and liquids that are contaminated to come in contact with people. Also, there are no probable side effects on using the mask. If the government approves of its marketing, the face mask can be distributed among the public to prevent the widespread of Novel Coronavirus.”

OHP sheet assembly

OHP sheet assembly

The management of SRM AP, Andhra Pradesh applauds Dr. Jayaprakash on designing the mask after relentlessly working on it for several days. Prof. Narayana Rao, Pro Vice-Chancellor of the University, has written to Adimulapu Suresh, Minister of Education, Andhra Pradesh, and Alla Kalikrishna Srinivas, Deputy Chief Minister of Andhra Pradesh, Minister for Health, Family Welfare and Medical Education, Andhra Pradesh, highlighting the importance of the facial cover and the many ways it can be regarded as a boon to the society as a whole. He said that the Face Shield would be beneficial to millions of students who would be attending regular classes once the educational institutions reopen.

- Published in Mechanical Engineering NEWS, News, Research News

Undergraduate students design e-bike for sustainable environment

Advancing the celebration, Prof D Narayana Rao, Pro Vice-Chancellor, SRM AP took the virtual podium to comment “Science and Technology is the driving force for the economic development of India. We need to encourage young scholars by providing a vibrant and conducive research environment. Expanding the frontiers of knowledge by triggering interest among students must be the priority of the institutions. Also, focus should be on translational research with societal applications through collaborative research to make our nation a global leader.”

The team comprises of undergraduate students – Mr Raviteja Reddy, Mr A Chaitanya, Mr P M Aditya, Mr K Praveen, K Yeshashwini, A Sravya, K Vasu, and G Priyanka along with faculty members – Dr Venkata N Nori, Associate Professor, and Dr Panchagnula Jayaprakash Sharma, Assistant Professor, Department of Mechanical Engineering. Aditya reveals, “We endured several challenges in various aspects of retrofitting the conventional petrol motorcycle. Also, designing a portable battery system, enhancing the performance of the Hub motor, Chassis improvements, etc. enriched our understanding of electric vehicles and manufacturing techniques.”

Conversion of IC engine bike to an e-bike is considered to be a potential business venture by the team. Sharing their forthcoming plans, Aditya informs, “We are working on additional designs and ideas to incorporate the best possible features to make the e-bike more reliable. We heartily thank Prof D Narayana Rao, Pro Vice-Chancellor, for his continuous support. Also, Dr Venkata Nori and Dr Jayaprakash propelled us to create a steadfast model by relentlessly helping us in improving our design to make our model more cost-effective.”

- Published in Mechanical Engineering NEWS, News, Research News

An Enthralling Webinar on “Applications of Artificial Intelligence in Aerospace Engineering”

On April 15, 2021, the Department of Mechanical Engineering, SRM University-AP, Andhra Pradesh, hosted a virtual lecture session with Dr B V N Ramakumar, Professor and HOD, Department of Aerospace Engineering, Dayananda Sagar University, Bangalore. Addressing the Webinar, Dr Lakshmi Sirisha Maganti and Dr Venkata Nori, Faculty, Department of Mechanical Engineering, handed over the podium to Dr Ramakumar. Initiating the discussion with a brief understanding of the background of Artificial Intelligence (AI), Dr Ramakumar described the AI Applications in Space, Civil and Defense industry. Apart from highlighting the overview and functionality of AI Applications in Aerospace Engineering, he outlined the challenges associated with it.

On April 15, 2021, the Department of Mechanical Engineering, SRM University-AP, Andhra Pradesh, hosted a virtual lecture session with Dr B V N Ramakumar, Professor and HOD, Department of Aerospace Engineering, Dayananda Sagar University, Bangalore. Addressing the Webinar, Dr Lakshmi Sirisha Maganti and Dr Venkata Nori, Faculty, Department of Mechanical Engineering, handed over the podium to Dr Ramakumar. Initiating the discussion with a brief understanding of the background of Artificial Intelligence (AI), Dr Ramakumar described the AI Applications in Space, Civil and Defense industry. Apart from highlighting the overview and functionality of AI Applications in Aerospace Engineering, he outlined the challenges associated with it.

Dr Ramakumar completed his bachelor’s from Ranchi University, and he pursued a master’s from Andhra University. Dr Ramakumar holds a Doctorate Degree from IIT Madras and has years of experience in research, academia and industry. Dr Ramakumar worked for Rolls Royce India Pvt Ltd and Honeywell Solutions Pvt Ltd. With contributions to the Auto Mechanics Industrial Sector, he also worked for the DMR Institute of Technology.

Dr Ramakumar was the visiting faculty at Manipal University. In terms of contribution to the field of engineering, he designed, developed, and analysed components for Boeing 777X, Airbus A350 and Honeywell HTF700 Engine Programme. Dr Ramakumar published papers in reputed National and International journals in addition to two patents to his credit.

Dr Ramakumar elucidated, “Artificial Intelligence is the broad sphere covering machine learning and deep learning as well. Moreover, a technique which mimics human behaviour”. Discussing the key players in the aviation industry, he explained the role of the mini-robots to capture the imagery clips of the inaccessible area in an aircraft. Implementation of the Artificial Reality techniques in the civil aviation industry is needed to reduce manual cost and time. AI applications manage the supply chain by gathering data as a part of the predictive measure. With the inclusion of automated tools, the civil aviation industry efficiently controls and optimises the security parameters.

During Dr Ramkumar’s proceeding, he added, “AI Application in aviation optimises the data related to flight scheduling, seat arrangement, cabin crew shift scheduling along with the management of the route mapping”. Starting from taking off to landing, AI Applications are being used widely in the aviation industry.

He further added that “Emerging as the dynamic technology, AI Applications marked their presence in the military intelligence too. Drones for military operations map the routes and record that in imagery forms to apprehend the nearby geographical location. The information stored in databases are sent and received without any manual meddling”.

Advancing to the next part of the discussion, Dr Ramakumar explained that “Speaking of the satellite link and communication, Robonauts are the new humanoid robots that would replicate the actual human beings by assisting in anything from gathering outer space information to exploring it”. Dr Ramakumar also propounds that “Productivity and Investment are few challenges amongst others that are common and would go hand in hand with the development of AI technology.” The discussion came to an end with an engaging Q&A session with the students followed by a Vote of Thanks by Dr Nori.

- Published in Departmental News, Mechanical Engineering NEWS, News, Webinars