Invited Talk on Understanding Microphysics of Raindrops for Accurate Rainfall Forecasting

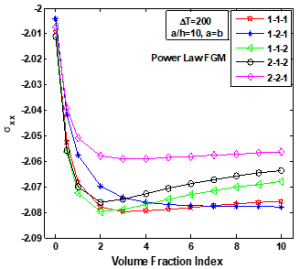

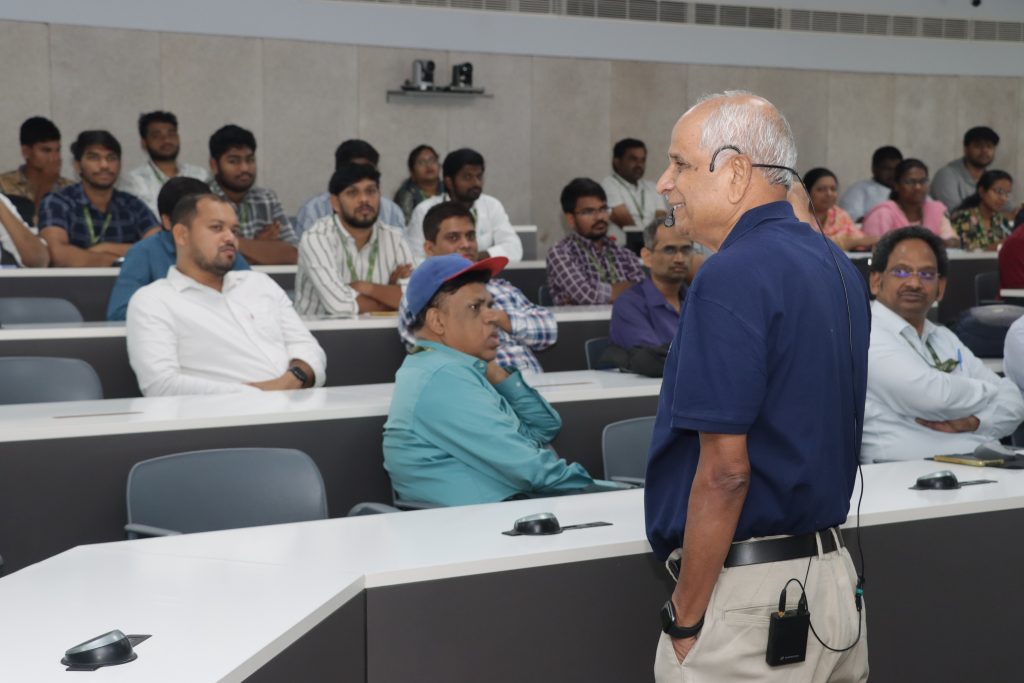

The Department of Mechanical Engineering hosted a Guest talk on “Understanding Microphysics of Raindrops for Accurate Rainfall Forecasting”. The session was presented by Prof. Kirti Chandra Sahu, distinguished Professor of the Department of Chemical Engineering at Indian Institute of Technology (IIT) Hyderabad, India. His research focuses on clouds and raindrops dynamics, interfacial fluid flows, and hydrodynamic instabilities.

The Department of Mechanical Engineering hosted a Guest talk on “Understanding Microphysics of Raindrops for Accurate Rainfall Forecasting”. The session was presented by Prof. Kirti Chandra Sahu, distinguished Professor of the Department of Chemical Engineering at Indian Institute of Technology (IIT) Hyderabad, India. His research focuses on clouds and raindrops dynamics, interfacial fluid flows, and hydrodynamic instabilities.

During the session Prof. Kirti Chandra Sahu emphasised the significance of understanding the microphysics of raindrops for accurate rainfall forecasting, highlighting the role of droplet formation, coalescence, and raindrop breakup under atmospheric conditions. He highlighted how progress in fluid dynamics, when integrated with computational modelling, can significantly strengthen weather prediction capabilities and contribute to climate-resilient strategies through interdisciplinary research. The event highlighted the role of fluid instabilities, surface tension effects, and computational modelling in understanding atmospheric microphysics. The session was highly interactive and informative, bridging the gap between theoretical fluid mechanics and real-world applications in weather forecasting.

The event was successfully led by a team of faculty members Dr Surfarazhussain S Halkarni, Dr Chandan Kumar, and Dr Manjesh Kumar, who played key roles in coordination, technical facilitation, and audience engagement. The talk concluded with an engaging Q&A session, where participants explored potential interdisciplinary collaborations and applications.

Prof. Kirti Chandra Sahu encouraged faculty members, research scholars, and students to explore this emerging domain, citing its growing relevance in tackling climate-related challenges. The event was a resounding success, fostering academic curiosity and encouraging further research.

About the Speaker :

Prof. Kirti Chandra Sahu received several prestigious recognitions, including the Young Scientist Awards from the Indian National Science Academy and the National Academy of Sciences, and the VASVIK Award.

He is a Fellow of the Indian Academy of Sciences and the Institute of Physics (UK). Prof. Sahu also serves as an Associate Editor for Industrial & Engineering Chemistry Research and is on the editorial board of Langmuir journal. He is currently a member of the External Affairs Committee of the American Physical Society’s Division of Fluid Dynamics (2024–2026).

- Published in Departmental News, Mechanical Engineering NEWS, News

Industrial Meet on Fracture Mechanics: Forging Industry-Academia Partnerships

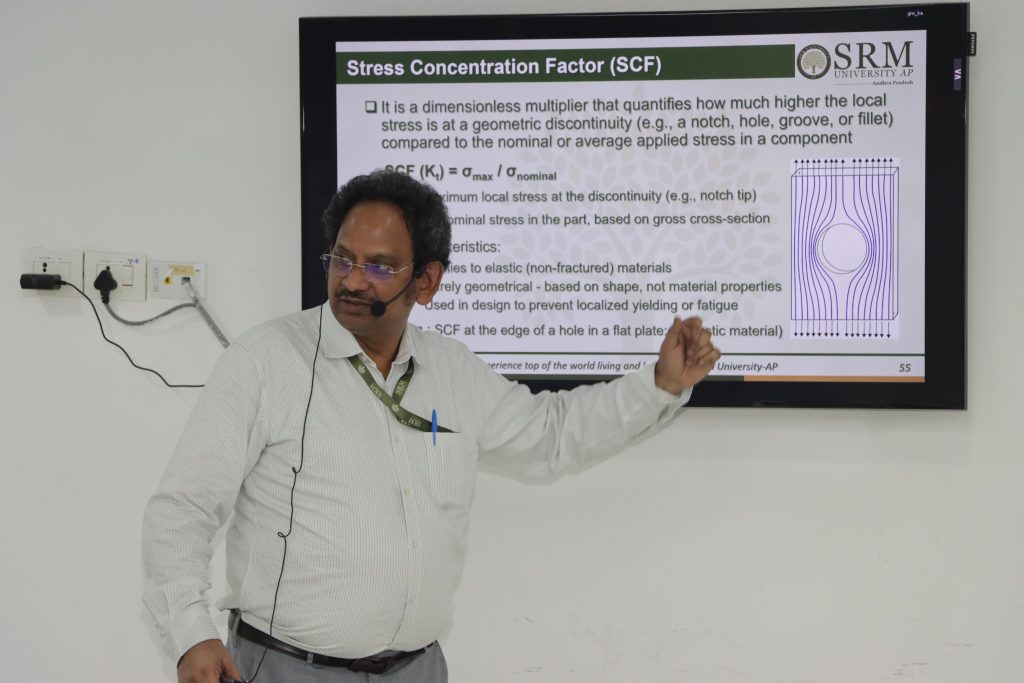

The Department of Mechanical Engineering organised a focused Industrial Meet on June 21, 2025, titled “Demystifying Fracture Mechanics for Industry: Safe Design, Analysis and Operation of Pressure Vessels, Piping & Pipelines & Green Hydrogen Storage and Transportation Equipment.” This specialised workshop was designed for professionals from well-established Refinery, Petrochemical and Oil & Gas, sectors and the emerging Green Hydrogen industry.

The industry meet commenced with a brief keynote address by Dr Dipak K Chandiramani, Independent Consultant (Mumbai) & Chair, ASME PVP Division, India, on the topic “Quality Assurance in Fabrication: Perspectives from Industry Standards.” His talk laid a strong foundational understanding, setting the stage for the central theme of the meet. visited the laboratories of the Department of Mechanical Engineering and discussed opportunities for commercialising the available facilities. He expressed interest in promoting our industrial training programs on ASME’s Master Class – Advanced Learning Programs webpage and invited faculty members to participate in the upcoming ASME code development committee meetings.

Dr Gurumurthy Kagita, Professor of Practice, Department of Mechanical Engineering, SRM AP, the main resource person for the event, shared his extensive industry experience relevant to the theme of the meet and explained the practical applications of fracture mechanics in the refinery, petrochemical, and oil & gas sectors, as well as in the emerging green hydrogen industry.

The meet began with an introduction to the key concepts of fracture mechanics, presented in a simple and accessible manner for industry professionals. Emphasis was placed on visual learning through graphics and animations rather than traditional classroom-style lectures. In the latter part of the session, the focus shifted to applying fracture mechanics in alignment with various international industry codes and standards. Several case studies were presented using in-house-developed software modules, including Brittle Fracture Screening, MPT envelopes for hydro-processing reactors, etc.

The meeting saw external participants from professionals across various industries, faculty members from the Department of Mechanical Engineering, and students, including both B.Tech. and Ph.D. scholars.

Several industry participants expressed strong interest in future collaboration with SRM University. Multiple organisations, including Anup Engineering, Jindal Renewable Pvt. Ltd., and Ratnamani Metals and Tubes Ltd., expressed interest in signing Memoranda of Understanding (MoUs) with SRM University for future collaboration in advanced engineering services. Several companies also expressed willingness to offer internships and placement opportunities to SRM AP students.

Industry representatives showed keen interest in collaborative research and consultancy projects, particularly in areas such as hydrogen pipeline design, digital twin tools, and numerical assessment of hydrogen-compatible materials.

These outcomes collectively highlight strong potential for long-term industry-academia partnerships and increased opportunities for students in training, research, and employment.

- Published in Departmental News, Mechanical Engineering NEWS, News, Workshop

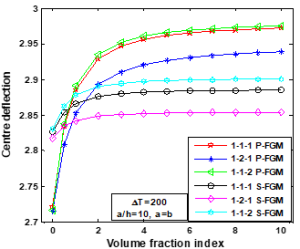

Analysing Thermo-mechanical Bending Behaviour of Sigmoid FGM Sandwich Plate

Dr Supen Kumar Sah, Assistant Professor at the Department of Mechanical Engineering presents his exclusive study on the thermo-mechanical bending behaviour of functionally graded material (FGM) sandwich plates using the Sinusoidal Shear Deformation Theory (SSDT) in his recent paper titled “Thermo-mechanical bending of power and sigmoid FGM sandwich plate using sinusoidal shear deformation theory”. The paper has been published in the Journal of Reinforced Plastics and Composites, having an impact factor of 3.2.

Abstract

This study examines the thermo-mechanical bending behaviour of functionally graded material (FGM) sandwich plates with temperature-dependent properties. FGMs, typically made from metal and ceramic, combine rigidity and high thermal resistance, and their properties are assumed to vary continuously in thickness. Using sigmoid and power law distributions, we analyse the smooth variation of properties and apply a one-dimensional heat conduction equation to determine temperature changes. The Sinusoidal Shear Deformation Theory (SSDT) is utilised to account for the sinusoidal distribution of shear stress while meeting traction-free boundary conditions. We derive the governing equations through Hamilton’s variational principle and Navier’s solution, resulting in closed-form solutions for center deflection, and normal and shear stresses of the plates. The analysis reveals that temperature-dependent properties and gradation indices significantly affect central deflection, normal stress, and shear stress. The SSDT results align well with existing shear deformation theory, confirming its accuracy.

Dr Sah collaborated with Dr Anup Ghosh from IIT Kharagpur on the research study. He aims to continue his research on FGMA and focus on the structural analysis of multidirectional Functionally Graded Material sandwich plates in the future.

- Published in Departmental News, Mechanical Engineering NEWS, News, Research News

Workshop on Current Trends in the Automotive Industry

The Department of Mechanical Engineering at SRM AP hosted a workshop on Atmanirbhar Bharat: Innovations in Lean Manufacturing for the Automotive Industry. The workshop focused on the evolving landscape of the automotive industry. Industry veterans Mr Narayan Vakil, an independent director with 40 years of experience across automotive components, and Mr Srikumar Srinivasan, Delivery Head at Tata Elxsi Ltd., led the workshop.

The Department of Mechanical Engineering at SRM AP hosted a workshop on Atmanirbhar Bharat: Innovations in Lean Manufacturing for the Automotive Industry. The workshop focused on the evolving landscape of the automotive industry. Industry veterans Mr Narayan Vakil, an independent director with 40 years of experience across automotive components, and Mr Srikumar Srinivasan, Delivery Head at Tata Elxsi Ltd., led the workshop.

The workshop delved into topics such as electric vehicles (EVs), automation, artificial intelligence (AI), and the Internet of Things allowing the attendees a chance to understand the principles of lean manufacturing and their crucial role in enhancing operational efficiency. Discussions also covered Industry 4.0 and its revolutionary impact on automotive production.

Participants were also offered insights on waste reduction strategies aimed at improving productivity while embracing sustainable manufacturing practices. The event also served as a platform for networking, fostering future collaborations between automotive manufacturers and technology providers.

- Published in Departmental News, Mechanical Engineering NEWS, News

Industrial Visit to Reliance Industries-KGD6 Oil & Gas

The Department of Mechanical Engineering under the School of Engineering and Sciences at SRM University-AP, organised an industrial visit on March 22, 2025 to Reliance Industries – KGD6 Oil & Gas, Andhra Pradesh.

The Industrial visit helped enhance the practical knowledge and industry exposure of the B.Tech & M.Tech students in the field of oil and gas extraction and learn first-hand the sustainable practices followed in the industry. The visit aligned with the students academic curriculum and prepared them for a future in the energy sector.

The visit was led by faculties, Dr Gurumurthy Kagita, Prof. Prakash Jadhav, Dr Satya Pramod Jammy, Dr Chandan Kumar, and Dr Supen Kumar Sah from the Department of Mechanical Engineering, who accompanied the students throughout the visit. During the visit, students gained insights of operational aspects of oil and gas industries, offshore and onshore adopted technologies, pollution control strategies, real-time monitoring, automation, control systems used in oil and gas operations and environmental management techniques. Experts from Reliance Industries-KGD6 Oil & Gas explained advanced drilling techniques, offshore and onshore extraction processes, and storage techniques of natural gases to our students. The visit also provided insights into safety protocols, automation in industrial processes and sustainability practices in the Oil & Gas industry.

The visit was highly beneficial for students as it bridged the gap between theoretical knowledge and real-world applications. It also offered an opportunity to interact with industry professionals and understand the challenges in oil and gas industries.

- Published in Departmental News, Mechanical Engineering NEWS, News

Bridging the Gap between Theory and Practical Learning

The Department of Mechanical Engineering at SRM University-AP organised an industrial visit to the Dr Narla Tata Rao Thermal Power Station. Dr Chandan Kumar and Dr Manjesh Kumar, faculty coordinators at the department accompanied the students during the visit.The visit was aimed to facilitate practical knowledge among students and to enhance their industry exposure.

The Department of Mechanical Engineering at SRM University-AP organised an industrial visit to the Dr Narla Tata Rao Thermal Power Station. Dr Chandan Kumar and Dr Manjesh Kumar, faculty coordinators at the department accompanied the students during the visit.The visit was aimed to facilitate practical knowledge among students and to enhance their industry exposure.

During the visit students were able to explore the various operational aspects of the power plant including boiler operations, turbine functioning, coal handling and environmental management techniques. The engineers from the plant also shared their expertise and offered practical demonstrations of the thermal plants’ functioning.

Students also got an opportunity to discuss the operational challenges and understand first hand the potential solutions to the problems. Interactions such as these allowed the students to make real time practical applications of the theoretical aspects learned.

The Department of Mechanical Engineering expressed gratitude to the management and staff of Dr Narla Tata Rao Thermal Power Station for their warm hospitality and invaluable learning experience. This visit was not only educational but also essential in bridging the gap between theory and practical application, contributing meaningfully to the academic and professional development of the students.

- Published in Departmental News, Mechanical Engineering NEWS, News

Exploring Composite Structures with Dr Subbareddy Daggumati

The Department of Mechanical Engineering hosted an invited talk on “Design of Composite Structures” on February 27, 2025. The session was delivered by Dr Subbareddy Daggumati, distinguished Associate Professor of the Department of Mechanical Engineering at Indian Institute of Technology (IIT) Tirupati, Andhra Pradesh, India. An expert in composite materials, structural mechanics, and computational modelling, Dr Subbareddy Daggumati, highlighted the significance of composite materials in aerospace, automotive, and structural applications in his talk.

The presentation covered key topics such as fatigue damage mechanisms, experimental analysis, predictive modelling, and recent advancements in composite material research. Participants, including faculty members, researchers, and students, actively discussed improving fatigue resistance through material selection, design optimization, and advanced testing techniques. A leading figure in advanced engineering research, Dr Subbareddy Daggumati also underscored the extensive research opportunities available for faculty, research scholars, and students interested in exploring the fatigue behaviour of composite structures. The event was highly informative, fostering academic exchange and encouraging further research into the fatigue behaviour of composite structures.

The event was presided over by Dr Lakshmi Sirisha Maganti, Head of the Department of Mechanical Engineering and Prof. Prakash Jadhav, Professor of the Department of Mechanical Engineering. The talk concluded with an interactive Q&A session, where attendees gained valuable knowledge on current challenges and future research directions in this field.

- Published in Departmental News, Mechanical Engineering NEWS, News

Enhancing Hydrogen Generation Efficiency through Machine Learning

The Department of Mechanical Engineering successfully hosted an Invited talk on “Hydrogen Gas as the Future Fuel for Sustainable Power Generation and Application of Machine Learning Techniques for Modeling of Hydrogen Generation by Chemical Reactions” on February 24, 2025. The session witnessed Prof. P. S. Robi, a distinguished Professor of the Department of Mechanical Engineering at the Indian Institute of Technology (IIT) Guwahati and Former Deputy Director of IIT Guwahati, Assam, India, as the esteemed speaker.

Prof. P S Robi highlighted the importance of hydrogen as a sustainable fuel, emphasising its potential to replace fossil fuels, reduce carbon emissions, integrate with renewable energy sources, and the role of research and industry collaboration in advancing its adoption to make hydrogen a viable energy source for a sustainable future. He also addressed key challenges in hydrogen adoption, particularly the need to overcome high production costs and storage limitations.

Furthermore, Prof. Robi emphasised the role of Machine Learning in enhancing hydrogen generation efficiency through data-driven modelling and optimisation. Potential research and collaboration prospects, advocating for stronger partnerships between academia, industry, and policymakers to accelerate the advancement and implementation of hydrogen technology, were extensively discussed. Additionally, Prof. P. S. Robi highlighted the myriad of research opportunities available for faculty, research scholars, and students interested in hydrogen generation.

The talk concluded with an interactive Q&A session, during which the participants actively engaged with the speaker. The session was attended by Dr Lakshmi Sirisha Maganti, Head of the Department of Mechanical Engineering, Dr Chandan Kumar, Assistant Professor and convenor of the event, along with the faculty, scholars and students of the university.

- Published in Departmental News, Mechanical Engineering NEWS, News

Industry 4.0 Readiness: Transforming the Future of Manufacturing

The Department of Mechanical Engineering concluded its 5-day intense Faculty Development Programme on Smart Manufacturing and Industry 4.0 organised with the objective of highlighting Smart Manufacturing to boost efficiency and sustainability, fostering collaboration among researchers, academicians, and industry experts and improving manufacturing practices and sustainability through innovation.

The Department of Mechanical Engineering concluded its 5-day intense Faculty Development Programme on Smart Manufacturing and Industry 4.0 organised with the objective of highlighting Smart Manufacturing to boost efficiency and sustainability, fostering collaboration among researchers, academicians, and industry experts and improving manufacturing practices and sustainability through innovation.

The FDP kick-started with a plenary lecture on Smart Manufacturing/Industry 4.0, followed by interactive sessions led by eminent speakers. The FDP witnessed industrial and academic stalwarts such as Prof. Ramesh Babu, IIT Chennai; Mr Amit Baddi, Samprama Digitech, Pune; Dr Rishi Relan, Siemens, Delhi; Prof. Kaushal Desai, IIT Jodhpur to name a few. The resource persons, experts in their specific realms, primed over 100+ participants from both in and around the varsity.

The participants had the opportunity to learn about big data analytics and machine-to-machine communication, real-time data collection and processing using IoT, and seamless integration of manufacturing system components. The FDP encouraged extensive discussions and knowledge sharing sessions, bestowing a pivotal opportunity for participants, educators and industry practitioners to immerse themselves in the future of manufacturing.

The FDP also offered the participants significant opportunities to contribute to the evolving manufacturing landscape, ultimately enhancing productivity, efficiency, and sustainability in their respective fields. Academic colloquiums such as these prove to be significant in readying the next cohort of engineers and technology enthusiasts to tackle the problems of tomorrow.

- Published in Departmental News, FDP, Mechanical Engineering NEWS, News

Faculty Collaborate on Interdisciplinary Innovation

In an inspiring collaboration, Prof. G S Vinod Kumar and Prof. Sheela Singh from the Department of Mechanical Engineering, Prof. Ranjit Thapa from the Department of Physics, and Dr Rajapandiyan Panneerselvam from the Department of Chemistry at SRM University – AP, along with PhD scholars Ms Harsha K and Ms Arunima J, have co-authored a compelling paper titled “Innovative Approaches to Enhancing the Tarnish Resistance of Silver Alloys.” This groundbreaking research focuses on developing new silver alloys that resist tarnishing, enhancing durability and aesthetic appeal for applications in the jewellery industry. Together, they are paving the way for innovative solutions that blend science with artistry.

In an inspiring collaboration, Prof. G S Vinod Kumar and Prof. Sheela Singh from the Department of Mechanical Engineering, Prof. Ranjit Thapa from the Department of Physics, and Dr Rajapandiyan Panneerselvam from the Department of Chemistry at SRM University – AP, along with PhD scholars Ms Harsha K and Ms Arunima J, have co-authored a compelling paper titled “Innovative Approaches to Enhancing the Tarnish Resistance of Silver Alloys.” This groundbreaking research focuses on developing new silver alloys that resist tarnishing, enhancing durability and aesthetic appeal for applications in the jewellery industry. Together, they are paving the way for innovative solutions that blend science with artistry.

Abstract

Silver and its alloys undergo tarnishing with time, which is a black stain on the surface due to the formation of Ag2S. Developing a tarnish resistant Ag alloy was attempted by alloying Ag with elements that form a passive oxide layer on the surface. Germanium is proven to provide better tarnish resistance to sterling silver alloy (92.5wt.% pure) which is available under the trade name of Argentium©. The present work investigates the tarnish resistance behaviour of sterling silver alloy (92.5wt.% pure) containing various additions of Copper, Zinc, Germanium, Aluminium, Beryllium, Titanium, Zirconium, and Magnesium. The alloys were prepared by melting and casting route, followed by Passivation Heat Treatment (PHT) to create a stable and continuous oxide layer. The temperature for PHT was optimized using thermogravimetry analysis (TGA) of the alloys prepared. An accelerated tarnish test was carried out to investigate the tarnishing behaviour of alloy samples obtained before and after PHT. The samples were characterized using XRD, SEM-EDX, TG-DSC, micro-Raman Spectroscopy, and XPS. The change in reflectance of the samples after the tarnish test is determined using UV-visible reflectance spectroscopy. The mechanism behind the tarnish resistance was derived using Density Functional Theory (DFT) by comparing sulphur (S2) and Oxygen (O2) adsorption energies (BE) of the alloying elements.

Explanation of the Research in layperson’s terms

Age-old silver pieces are found in different colours ranging from light yellow(silver Jewellery pieces after a few weeks of usage) to black(archaeological silver pieces). They look different in terms of the metallic white colour and lustrous appearance from fresh silver. This demeans silver and thus affects its market. The major cause of the staining of silver is the interaction of individual silver particles with some elements found common in the atmosphere. We work on the prevention of this staining of silver. For the study, silver is incorporated with other elements which makes silver less interacting with staining elements in the atmosphere. These additional elements create a layer over silver so that it is protected. The appropriate elements are identified by using modelling using computer software. After obtaining appropriate elements, the experimental trials are also done with the same elements until stainless silver is obtained. Then, what happens to the added elements inside silver is also studied by using modern microscopic technics.

Practical/Social Implications of the Research

The major application of the invention is in the jewellery industry. The problem of tarnishing is an age-old threat in jewellery making. The alloys we proposed could be used to make quality silver jewellery/articles that can sustain the colour and lustre for a longer period. This will stop the hesitation from jewellery designers and industries to try intricate designs in silver and find a better market for them. The alloys based on the proposed composition show good grain refinement and thus high hardness. This strengthens the soft silver and improves the range of its applications from low hardness articles to high. The alloys based on the proposed composition have high tensile strength. They deform plastically for a wide range of stress values and will not break easily.

Collaborations:

Waman Hari Pethe & Sons Jewellery

Future Research Plans:

1. Corrosion studies of silver alloys to understand the behaviour in solutions having compositions similar to that of sweat.

2. Study of mechanical properties of silver alloys to develop workable alloys of sterling silver which could be used for jewellery manufacturing

3. Identification of elements having better oxide layer formation when alloyed with silver, by using computational techniques and experimental studies of their properties.

Link to the article:

https://www.sciencedirect.com/science/article/pii/S2238785424024633

- Published in Chemistry-news, Departmental News, Mechanical Engineering NEWS, News, Physics News, Research News