What happens when you can use natural waste like orange peels and rice husks to extract valuable metals from old batteries, electric vehicles, etc.? Exploring innovative and eco-friendly methods to recover useful metals, Dr Deblina Dutta, Assistant Professor, Department of Environmental Science and Engineering, and her research scholars, Ms Syed Suffia Iqbal and Mr Pranav Prashant Dagwar, have published a paper titled “Recovery of metals from spent lithium-ion batteries using agricultural waste, applications and circularity framework” in the prestigious Q1 journal Separation and Purification Technology having an impact factor of 8.2.

Abstract

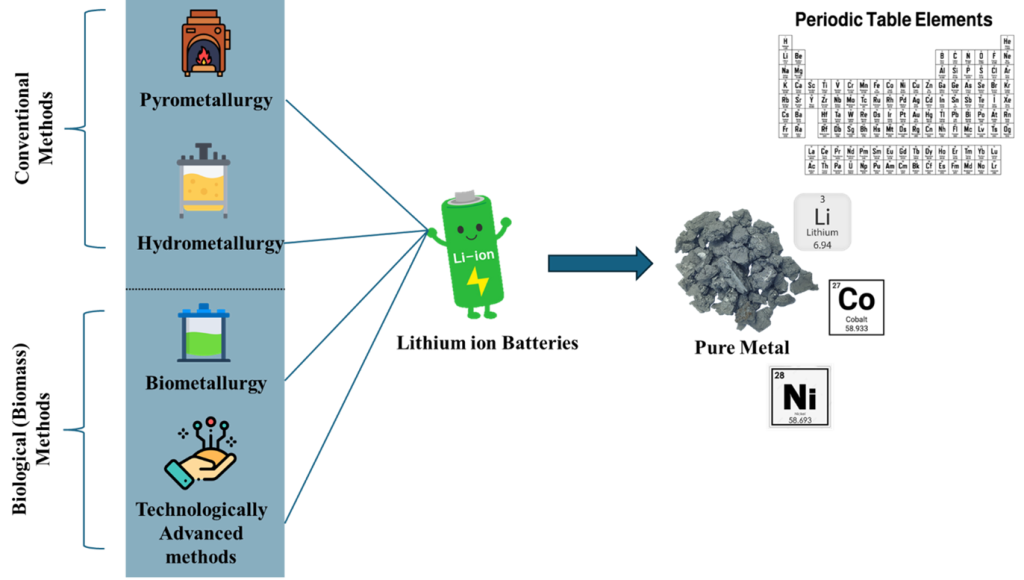

This research explores an innovative, sustainable method to recover valuable metals (Li, Co, Ni, Mn) from spent lithium-ion batteries (LIBs) using agricultural waste such as rice husk, orange peels, tea waste, and sugarcane molasses. These organic wastes serve as eco-friendly, cost-effective leaching agents. The study compares conventional and biomass-based recovery methods, evaluates environmental impacts, and aligns the approach with circular economy principles to promote green technology and resource optimization.

Practical Implementation/ Social Implications of the Research

- Eco-friendly Recycling: Offers an alternative to hazardous chemical recycling by using biodegradable, non-toxic agricultural waste.

- Waste Valorisation: Transforms agricultural waste into a valuable resource, reducing landfill and open burning.

- Resource Recovery: Helps recover critical battery metals, reducing dependence on mining.

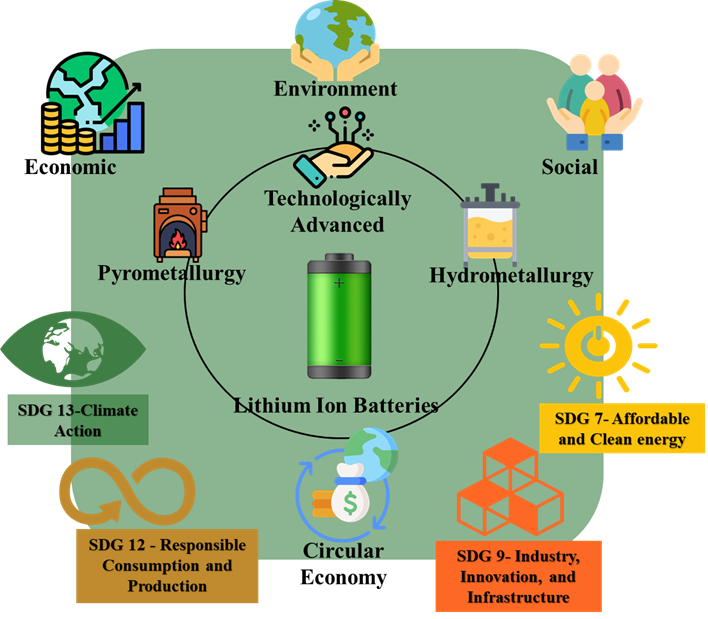

- Circular Economy: Supports sustainability goals by promoting a closed-loop recycling system.

- Policy Relevance: Aligns with SDGs such as clean energy (SDG 7), sustainable industries (SDG 9), and responsible consumption (SDG 12).

Collaborations

- Ain Shams University, Egypt

- Central Metallurgical R&D Institute (CMRDI), Egypt

Future Research Plans

- Scale up biomass-based metal recovery to pilot or industrial level.

- Develop hybrid leaching methods combining microbes and green solvents.

- Expand to rare earth element (REE) recovery from other waste streams.

Link to the article

Fig. 2. Conventional and technologically advanced process for recycling LIBs.

Fig. 9. Sustainability and circular economic applications in LIBs management.