In an attempt to recycle industrial mineral waste into useful products, Dr Jaidev Kaushik from the Department of Chemistry has worked on synthesising copper-based particles that use light to convert carbonate-rich materials like marble dust into acetic acid, a valuable chemical used in industry and fuel production. He has published his research in a paper titled “Photocatalytic Upcycling of Marble Waste into Acetic Acid” in the prestigious Journal of Materials Chemistry A, having an impact factor of 10.7.

The particles drive the reaction efficiently by illuminating the green light on a mixture of the material and hydrogen peroxide solution. He has also tested the method on other carbonate wastes like chalk dust and scale, showing its potential for recycling industrial mineral waste into useful products.

Abstract

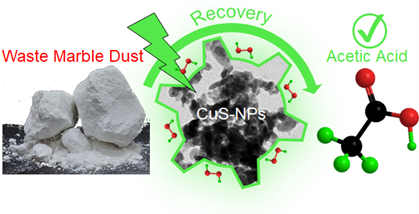

In this study, disk-shaped copper sulfide nanoparticles (CuS-NPs) were synthesised via a simple co-precipitation method and used as a photocatalyst for the reduction of carbonate species derived from marble dust into acetic acid (AcOH), an important industrial and biofuel precursor. The photocatalytic reaction was carried out under monochromatic light (525 nm) in a hydrogen peroxide–water mixture, which served as an electron and radical-rich medium. Key parameters such as solvent composition, light source, catalyst concentration and reaction time were optimised to get the maximum yield of AcOH. The reaction mechanism was investigated using radical scavenging experiments. The practical applicability of the approach was further tested on two additional real-life carbonate waste materials, i.e. chalk dust and scale.

Practical Implementation/ Social Implications of the Research

This research offers a sustainable method to convert carbonate-rich industrial wastes like marble dust, chalk dust, and scale into acetic acid, which is widely used in the chemical, pharmaceutical, and biofuel industries. By using light-driven reactions with safe, low-cost materials, the process reduces environmental pollution, supports waste valorisation, and contributes to a circular economy. It can be implemented in industries that generate carbonate waste, promoting green chemistry and lowering dependence on fossil-based raw materials.

Collaborations

Dr Sumit Kumar Sonkar (MNIT Jaipur, India)

Future Research Plans

- The adsorption/photodegradation-assisted quick and efficient removal of next-generation advanced pollutants such as microplastic, pesticides, pharmaceutical waste, etc., by hydrophobic carbon aerogel and their doped and functionalised versions.

- Utilising waste-derived heterogeneous catalysts in organic transformation reactions.

- Selective sensing of toxic metal ions/biomarkers/biomolecules using fluorescent nanomaterials.

- Upcycling of carbonates/CO2 via photo/thermal assisted catalysed reactions to get C1 and C2 hydrocarbons (green fuel).

- Reduction of nitrates/N2 via photo/thermal-assisted catalysed reactions to ammonia.

Link to the article